The EEOICPA was passed in 2000. It provides compensation to workers who became ill as a result of their employment manufacturing nuclear weapons in the USA, as well as their spouses, children, and grandchildren.

Are you eligible for compensation? If you or a family member worked at this or another AWE or DOE facility and became ill, you may be entitled to compensation of up to $400K plus medical benefits. Call EEOICPA Counsel Hugh Stephens at 1-855-548-4494 or fill out our free claim evaluation, We can help even if you’ve already filed, even if your claim was denied!

Here, we have compiled publicly available information and documentation about the facilities covered by the Act to clarify how their activities relate to the Energy Employees Occupational Illness Compensation Program Act.

Los Angeles Area:

Below is a list of facilities covered by the EEOICPA in Los Angeles and Southern California. Please click on the facility’s name to scroll to its description:

AREA IV OF THE SANTA SUSANA FIELD LABORATORY

ATOMICS INTERNATIONAL

CANOGA AVENUE FACILITY

CERADYNE, INC. (COSTA MESA)

CERADYNE, INC. (SANTA ANA)

DE SOTO AVENUE FACILITY

DOWNEY FACILITY

ELECTRO CIRCUITS, INC.

GENERAL ATOMICS

HIGH ENERGY RATE FORGING (HERF) FACILITY

HUNTER DOUGLAS ALUMINUM CORP.

LABORATORY OF BIOMEDICAL AND ENVIRONMENTAL SCIENCES

LEBOW

PHILCO-FORD CORPORATION

________________________________________________________________________________

AREA IV OF THE SANTA SUSANA FIELD LABORATORY

Also Known As: Nuclear Development Field Laboratory (NDFL), Liquid Metal Engineering Center (LMEC), Energy Technology Engineering Center (ETC)

State: California

Location: Santa Susana, Area IV

Time Period: DOE 1955-1988; DOE remediation 1988-present

Facility Type: Department of Energy

Facility Description:

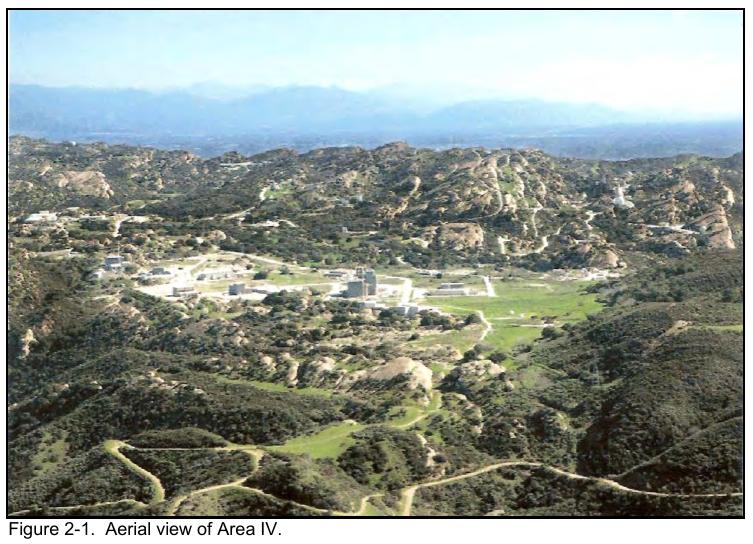

The Santa Susana Field Laboratory (SSFL) is located in eastern Ventura County, California, and borders Los Angeles County. TheSSFL is divided into four administrative and operational portions based on ownership and operations. Area IV was devoted to nuclear operations. It is Area IV that is covered under EEOICPA as a DOE facility.

Coverage includes, but is not necessarily limited to the following operations:

- The Energy Technology Engineering Center (ETEC), the Nuclear Development Field Laboratory (NDFL), and the Liquid Metal Engineering Center (LMEC). This also includes the Sodium Reactor Experiment Facility, the Kinetics Experiment Water Boiler Facility, the Water Boiler Neutron source (which is also known as the AE-6/L-85 Facility), the Organic Moderated Reactor, as well as facilities in Area IV associated with the Systems for Nuclear Auxiliary Power (SNAP) Program; the Sodium Graphite Reactor Critical Facility, the Shield Test Experiment/Shield Test Irradiation Reactor Facility, the Advanced Epithermal Thorium Test Facility, the Hot Lab Facility, the Fuel Storage Facility, the Radioactive Measurement Facility, the Radioactive Material Handling Facility, the Van De Graaff Accelerator Facility and the Radiation Instrument Calibration Laboratory.

- Decontamination, decommissioning and demolition of radiological facilities in Area IV has been funded by the DOE beginning in the 1970’s, but predominantly since 1988.

Throughout the course of operations in Area IV, the potential for beryllium exposure existed.

Contractors: The Boeing Company (1996-present); Rockwell International (1973-1996); North American Rockwell (1968-1973); North American Aviation (1955-1967).

NIOSH:

Review of the NIOSH Site Profile for the Santa Susana Field Laboratory

Listing:

Area IV of the Santa Susana Field Laboratory is listed as an Department of Energy (DOE) site under the EEOICPA.

Classes:

The SEC classes for Area IV of the Santa Susana Field Laboratory include:

All employees of the Department of Energy (DOE), its predecessor agencies, and DOE contractors and subcontractors who worked in any area of Area IV of the Santa Susana Field Laboratory for a number of work days aggregating at least 250 work days from January 1, 1955 through December 31, 1958, or in combination with work days within the parameters established for one or more other classes of employees in the SEC.

All employees of the Department of Energy, its predecessor agencies, and their contractors and subcontractors who worked in any area of Area IV of the Santa Susana Field Laboratory from January 1, 1959 through December 31, 1964, for a number of work days aggregating at least 250 work days, occurring either solely under this employment or in combination with work days within the parameters established for one or more other classes of employees included in the SEC.

History:

Area IV of Santa Susana Field Laboratory is a section of a now closed research facility located in California about 30 miles northwest of Los Angeles. In 1947, the site was chosen for testing liquid-propelled rocket engines, the placement of nuclear reactors, and a U.S. government sponsored liquid metals research center. The area was divided into four production areas (I-IV) and two buffer areas. Production area IV was used mainly for nuclear reactor experimentation. More than ten nuclear reactors were built in Area IV and at least four of them suffered fires. In 1959, a partial nuclear meltdown occurred. A massive cleanup was started by DOE and NASA in 2010 and is scheduled to be completed in 2017. The major portion of the land will be turned into a park and permanently restricted to nonresidential and noncommercial use.

Compensation:

As of 07/19/2015, the total compensation paid under Parts B and E of the EEOICPA, including medical compensation, for workers suffering from the effects of having worked at Area IV of the Santa Susana Field Laboratory is $54,715,007. Click here for a current accounting of compensation paid to former Area IV of the Santa Susana Field Laboratory Workers under the EEOICPA.

Area IV of the Santa Susana Field Laboratory Workers:

If you or your parent worked at this or any other DOE or AWE facility and became ill, you may be entitled to compensation of up to $400K plus medical benefits from the US Department of Labor. Call EEOICPA Counsel Hugh Stephens at 1-855-EEOICPA (336-4272) or fill out the form to the right, whether your claim has been accepted or denied. We can help with all OWCP (Federal Workers Compensation) claims, impairments, wage loss and health care. 2495 Main Street, Suite 442 Buffalo, NY.

Videos:

Further History of the Santa Susana Field Laboratory can be seen below:

Another perspective of the activities at Santa Susana can be seen in this video:

Some more personal histories of the activities at Area IV of the Santa Susana Field Laboratory, specifically concerning a meltdown that occurred at the site in 1959, can be seen below:

Part I –

Part II –

________________________________________________________________________________

ATOMICS INTERNATIONAL

State: California

Location: Los Angeles and Ventura Counties

Time Period: BE 1955-1966

Facility Type: Beryllium Vendor

Facility Description: The Atomics International Division of North American Aviation is a statutory beryllium vendor under the EEOICPA. Atomics International worked with beryllium and radioactive materials under contract with the Atomic Energy Commission at numerous locations. These locations include, but are not necessarily limited to, Area IV of the Santa Susana Field Laboratory, portions of the Downey facility, the Vanowen Building at the Canoga facility and the De Soto facility.

Listing:

Atomics International is listed as a Beryllium Vendor (BE) under the EEOICPA.

Compensation:

As of 03/15/2015, the total compensation paid under Part B of the EEOICPA, including medical compensation, for workers suffering from the effects of having worked at Atomics International is $7,978,337.Click here for a current accounting of compensation paid to former Atomics International Workers under the EEOICPA.

Atomics International Workers:

If you or your parent worked at this or any other AWE facility and became ill, you may be entitled to compensation of up to $150K plus medical benefits from the US Department of Labor. Call EEOICPA Counsel Hugh Stephens at 1-855-EEOICPA (336-4272) or fill out the form to the right, whether your claim has been accepted or denied.

We can help with all OWCP (Federal Workers Compensation) claims, impairments, wage loss and health care. 2495 Main Street, Suite 442 Buffalo, NY.

________________________________________________________________________________

CANOGA AVENUE FACILITY

State: California

Location: Los Angeles County

Time Period: DOE 1955-1960

Facility Type: Department of Energy

Facility Description:

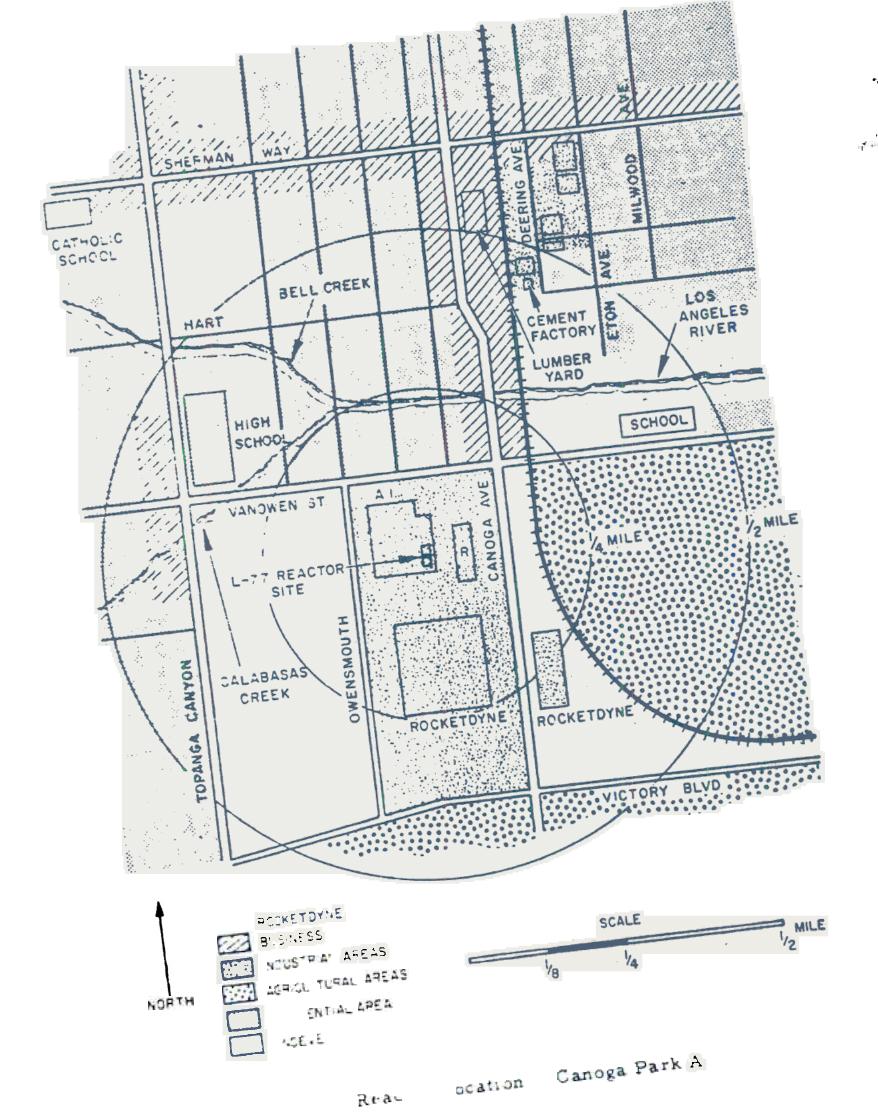

Under an operating contract with the Atomic Energy Commission (AEC), North American Aviation performed research and development into the peaceful uses of nuclear energy at the Canoga Avenue Facility in Canoga Park, CA. This work was previously performed at North nAmerican Aviation’s Downey Facility, but was moved to Canoga Avenue at the very end of 1955. Principal work performed included design,development and radiochemistry. Beryllium machining is also believed to have occurred in there.

The Nuclear Regulatory Commission concluded in its 1995 report on the facility that it “was found to be free of radioactive materials which indicated that the area had been successfully remediated… in the past.”

CONTRACTOR: North American Aviation 1955-1960

Listing:

Canoga Avenue Facility is listed as a Department of Energy (DOE) site under the EEOICPA.

Special Exposure Cohort (SEC) Classes:

The SEC classes for Canoga Avenue Facility include:

All employees of the Department of Energy, its predecessor agencies, and its contractors and subcontractors who worked at the Canoga Avenue Facility, Los Angeles County, California, from January 1, 1955 through December 31, 1960 for a number of work days aggregating at least 250 work days, occurring either solely under this employment or in combination with work days within the parameters established for one or more other classes of employees in the Special Exposure Cohort.

Job Titles and/or Job Duties covered by the SEC class include:

All workers employed by North American Aviation who worked in any areas in any job capacity.

History:

Atomics International conducted radiological operations in the Vanowen Building on Canoga Avenue in Canoga Park, California from December, 1955 until late 1959. The work included the design, development, and operation of enriched uranyl sulfate reactors and radiochemistry. In 1960, all of these activities were moved to a new facility and all operations in the Vanowen Building ceased. Surveys carried our by Atomics International and the Nuclear Regulatory Commission indicated that there is no residual radioactivity in the Vanowen Building, in the soil and vegetation or groundwater in the vicinity of the building. Demolition of the Vanowen Building was completed in 2006.

Canoga Avenue Facility was formerly part of Energy Technology Engineering Center, Canoga Complex.

Compensation:

As of 09/07/2015, the total compensation paid under Parts B and E of the EEOICPA, including medical compensation, for workers suffering from the effects of having worked at the Canoga Avenue Facility is $48,551,164. Click here for a current accounting of compensation paid to former Canoga Avenue Facility Workers under the EEOICPA.

Canoga Avenue Facility Workers:

If you or your parent worked at this or any other DOE or AWE facility and became ill, you may be entitled to compensation of up to $400K plus medical benefits from the US Department of Labor. Call EEOICPA Counsel Hugh Stephens at 1-855-EEOICPA (336-4272) or fill out the form to the right, whether or not you have already filed a claim, and even if your claim has been accepted or denied.

We can help with all OWCP (Federal Workers Compensation) claims, impairments, wage loss and health care. 2495 Main Street, Suite 442 Buffalo, NY.

*Historical Operations (1956-60)

In 1956, Atomics International (AI) was formed as a division of North American Aviation. AI performed R&D into the peaceful uses of nuclear energy. Between 1956 and 1960, this work was performed at the Vanowen building at the Atomics International (now Rocketdyne) facility on Canoga Avenue in Canoga Park, CA. Principal work performed at the Vanowen facility included design, development and operation of small, aqueous, 93% enriched uranyl sulfate, reactors, named L-47 and L- 77; reactor design, fuel development, and radiochemistry.

Reactor Max Power (watts) License Period of Operation

L-47 5 R-19 August 1957 -June 1958

L-77 10 R-40 May 1958 -February 1960

Both reactors were licensed by the U.S. Atomic Energy Commission (ABC) and operations were routinely inspected by ABC staff. The location of both reactors was in the southeast comer of the Vanowen building in what is now the loading dock area.

In 1960, AI moved to its new facility on De Soto Ave. in Canoga Park, and all radiological activities were transferred to De Soto.

** Canoga Park

AEC-funded activities at Rockwell’s Canoga Park, California, occurred in the Vanowen Building from approximately 1954 to 1960. This work had been performed at North American Aviation’s Downey Facility, but was moved to Canoga Avenue at the end of 1955. Principal work in the Vanowen Building included design, development, and operation of small aqueous fuel reactors, fuel development, and radiochemistry, and beryllium machining is believed to have occurred. The reactors activities involved the construction of small 10-W aqueous uranyl sulfate homogeneous reactors named L-47 and L-77 for use in training institutions. Reactor fueling occurred only after the reactors were installed at the training institutions. A few fuel elements for the organic moderated reactor were fabricated at this facility.

Facilities where AEC-funded work took place within the Vanowen Building included the machine shop (where some beryllium machining took place), a radiochemical laboratory, and office space. The wastewater from all facilities except the laboratory discharged into a common treatment plant. The wastewater from the radiochemical laboratory went to a clarifier, where it was tested for radioactivity before being released to the sanitary sewer if it was below established standards. The sludge from the clarifier was disposed of in a government repository or an AEC site for low-level waste.

Once the AEC work was completed, the clarifier was surveyed for radioactivity, determined to be within acceptable standards, and backfilled. The transfer lines from the clarifier to the sewer main could still be present, but they are not in use.

**Source

________________________________________________________________________________

CERADYNE, INC. (COSTA MESA)

State: California

Location: Costa Mesa

Time Period: 1987; 1990-1996

Facility Type: Beryllium Vendor

Facility Description: Ceradyne sold beryllium-graphite composite materials to the Y-12 plant in Oak Ridge in 1987 and between 1990 and 1996.

Listing:

Ceradyne, Inc.(Costa Mesa) is listed as a Beryllium Vendor (BE) under the EEOICPA.

Compensation:

As of 03/15/2015, the total compensation paid under Part B of the EEOICPA, including medical compensation, for workers suffering from the effects of having worked at Ceradyne, Inc.(Costa Mesa) is $183,553. Click here for a current accounting of compensation paid to former Ceradyne (Costa Mesa) Workers under the EEOICPA.

Ceradyne, Inc.(Costa Mesa)Workers:

If you or your parent worked at this or any other AWE facility and became ill, you may be entitled to compensation of up to $150K plus medical benefits from the US Department of Labor. Call EEOICPA Counsel Hugh Stephens at 1-855-EEOICPA (336-4272) or fill out the form to the right, whether or not you have already filed a claim, and even if your claim has been accepted or denied.

We can help with all OWCP (Federal Workers Compensation) claims, impairments, wage loss and health care. 2495 Main Street, Suite 442 Buffalo, NY.

________________________________________________________________________________

CERADYNE, INC. (SANTA ANA)

State: California

Location: Santa Ana

Time Period: 1977-1988

Facility Type: Beryllium Vendor

Facility Description: Ceradyne provided beryllium parts, and possibly powder, to the Y-12 plant.

Listing:

Ceradyne, Inc. (Santa Ana) is listed as a Beryllium Vendor (BE) under the EEOICPA.

Compensation:

As of 03/15/2015, the total compensation paid under Part B of the EEOICPA, including medical compensation, for workers suffering from the effects of having worked at Ceradyne, Inc. (Santa Ana) is $910,127. Click here for a current accounting of compensation paid to former Ceradyne (Costa Mesa) Workers under the EEOICPA.

Ceradyne, Inc. (Santa Ana) Workers:

If you or your parent worked at this or any other AWE facility and became ill, you may be entitled to compensation of up to $150K plus medical benefits from the US Department of Labor. Call EEOICPA Counsel Hugh Stephens at 1-855-EEOICPA (336-4272) or fill out the form to the right, whether or not you have already filed a claim, and even if your claim has been accepted or denied.

We can help with all OWCP (Federal Workers Compensation) claims, impairments, wage loss and health care. 2495 Main Street, Suite 442 Buffalo, NY.

________________________________________________________________________________

DE SOTO AVENUE FACILITY

State: California

Location: Los Angeles County

Time Period: DOE 1959-1995; DOE Remediation 1998

Facility Type: Department of Energy

Facility Description:

In 1959, the Atomics International Division of North American Aviation moved to its new facility on De Soto Avenue. AEC/DOE work conducted at this location included engineering design, construction, and nuclear fuel fabrication. The facility also had a radio chemistry laboratory and a gamma irradiation facility. The fuel fabrication facility was used to produce a variety of different fuel elements for test reactors. AEC-sponsored work involving the manufacture of beryllium-containing parts also took place at this site. Fuel fabrication was terminated in 1984, however small scale laboratory research work on gamma irradiation and analysis of radioactive samples continued until 1995. A DOE-owned mass spectrometer at this location was removed from the premises and sent to the Pacific Northwest National Laboratory in 1995.

Remedial activities occurred at various times in the 1980’s followed by license termination by the Nuclear Regulatory Commission. In 1998, decontamination and decommissioning of the mass spectrometer laboratory, funded by the DOE was performed by The Boeing Company. In 1998, decontamination and decommissioning of the state-licensed gamma irradiation facility was performed by The Boeing Company.

CONTRACTORS: The Boeing Company (1996-1998); Rockwell International (1973-1996); North American Rockwell (1967-1973): North American Aviation (1959-1967).

Listing:

De Soto Avenue Facility is listed as a Department of Energy (DOE) site under the EEOICPA.

Classes:

All employees of the Department of Energy, its predecessor agencies, and their contractors and subcontractors who worked at the De Soto Avenue Facility in Los Angeles County, California, from January 1, 1959 through December 31, 1964, for a number of work days aggregating at least 250 work days, occurring either solely under this employment or in combination with work days within the parameters established for one or more other classes of employees included in the Special Exposure Cohort.

(Note: This class was established from Petition 168)

Compensation:

As of 08/2015, the total compensation paid under Parts B and E of the EEOICPA, including medical compensation, for workers suffering from the effects of having worked at De Soto Avenue Facility is $44,849,020. Click here for a current accounting of compensation paid to former De Soto Avenue Facility Workers under the EEOICPA.

De Soto Avenue Facility Workers:

If you or your parent worked at this or any other DOE or AWE facility and became ill, you may be entitled to compensation of up to $400K plus medical benefits from the US Department of Labor. Call EEOICPA Counsel Hugh Stephens at 1-855-EEOICPA (336-4272) or fill out the form to the right, whether your claim has been accepted or denied.

We can help with all OWCP (Federal Workers Compensation) claims, impairments, wage loss and health care. 2495 Main Street, Suite 442 Buffalo, NY.

*NIOSH Site Profile:

Radiological operations occurred at the DeSoto Facility from 1959 to the mid-1990s. AI used nuclear fuel material and other radioactive materials in Buildings 101 and 104 from 1959 to 1983. A much-reduced level of work was continued by Rocketdyne in Building 104 into the mid-1990s. Before 1984, Buildings 101 and 104 were designated as 001 and 004. Much of the historical documentation refers to these building numbers. The following paragraphs briefly summarize the nuclear operations in these buildings.

L-77 Reactor (NRC Licensed). The L-77 small research reactor operated in Room 416-61 of Building 104 from 1960 to 1976. The L-77 was a low-power (10 W) reactor using enriched uranyl sulfate solution. The L-77 was a prototype teaching reactor sold to many universities and around the world. The laboratory housing L-77 was decommissioned and decontaminated in the late 1970s. The NRC released the facility for unrestricted use and terminated the reactor’s license in February 1982.

Advanced Test Reactor (ATR) Fuel Fabrication and Supporting Activities. NRC-licensed fuel fabrication operations were conducted in the northern section of the first floor of Building 101, with radiochemistry support operations conducted on the first and second floors of Building 104. These support activities included hot chemistry laboratories (east section of second floor), an emission spectroscopy laboratory (Room 411-72, first floor), and an X-ray diffraction laboratory (Room 411-58, first floor). The fuel fabrication facility produced a variety of different fuel elements for test reactors. Many fuel manufacturing programs began in 1959 using 2% to 93% enriched uranium metal and composites. Some of the work involved developing uranium-aluminum alloys and, because of the uranium, occurred in sealed gloveboxes. One of the larger programs was fuel manufacture for the ATR using uranium-aluminum (UAlX) powder with an enrichment of 93%. Fuel manufacturing ended in 1983. In addition, AEC-sponsored work involving the manufacture of beryllium-containing parts took place at this site.

D&D of Buildings 101 and 104 included removal of all fuel and radioactive materials and waste; removal of contaminated equipment, drain lines, tanks, and ventilation ducts; and cleaning of all surfaces including floors, walls, and ceilings.

Gamma Irradiation Facility (GIF). This state-licensed aboveground vault in Building 104 used sealed 137Cs and 60Co sources for radiation hardening tests of electronic components and for food irradiation research. The Gamma Irradiation Facility consisted of Rooms 41M-11 and 41M-11A on the northeast corner of Building 104. Activity ceased in the late 1980s, and the sources were shipped off the site for recycling in the early 1990s. Bi-annual leak checks of these sources detected no leaks. In 1995, a Rocketdyne survey of the GIF verified that it was not contaminated.

Mass Spectroscopy Laboratory (Helium Laboratory). Up until 1995, Rocketdyne used the state- licensed Mass Spectroscopy Laboratory to analyze miniature radioactive specimens of neutron-irradiated nonfissile metals from DOE and international reactors for helium content. The Mass Spectroscopy Laboratory consisted of Rooms 414-69, 416-72, 414-75, 416-76, 416-76A, 414-77, 416-80, 416-80A, and 414-81 in the northeast section of the 1st floor of Building 104. Operations of the DeSoto Mass Spectrometer Laboratory generated very small quantities of radioactive, hazardous, and mixed waste, including radioactive solvents, solvent wipes, and acids shipped from other U.S. and international research organizations. In 1995, the equipment was shipped to Pacific Northwest National Laboratory in Richland, Washington, where it continues to be used.

Fuel fabrication was terminated in 1984, but small-scale laboratory research work on gamma irradiation and analysis of radioactive samples continued until 1995. Remedial activities occurred at various times in the 1980s followed by NRC license termination. In mid-1998, all remaining equipment, interior walls, and drain lines were removed, and the facility was decontaminated. Residual contamination was low level and confined to the laboratory. No elevated radiation levels or contamination outside the laboratory were detected before or during D&D.

Former sewage lines connecting sinks and showers at Building 101 were plumbed into a network that discharged into a pair of 1,500-gal steel holding tanks. The tanks allowed sufficient time for sampling and analysis of the sanitary water before discharge to the main municipal sewer line. If the concentration of radionuclides was below the MPC, the water was released to the municipal sewer. Overly contaminated water would have been transported to the RMDF for evaporation, but no water in the holding tanks was ever above the MPC. During decommissioning of the facility in the 1980s, radioactive contamination of the small areas of soils adjacent to some of the drain lines was slightly above acceptable limits. Approximately 10 of 140 soil samples had activities in the range of 50 to 80 pCi/g in comparison to the NRC limit of 48 pCi/g. D&D included the removal of the holding tanks and excavation of contaminated soil. The outflow lines from the holding tanks to the main sewer between Buildings 101 and 104 remain in place.

*Source

________________________________________________________________________________

DOWNEY FACILITY

Also Known As: Downey Facility was formerly part of Energy Technology Engineering Center.

State: California Location: Los Angeles County

Time Period: DOE 1948-1955

Facility Type: Department of Energy

Facility Description:

Under an operating contract with the Atomic Energy Commission (AEC), North American Aviation operated a 2 MeV Van De Graaff accelerator at Downey. In addition, the AEC funded a four-watt Water Boiler Neutron Source Reactor at the Downey facility. Start up for the reactor was in April of 1952. This small research reactor was moved to Area IV of the Santa Susana Field Laboratory in 1955. Personnel and operations from Downey moved to the new Canoga Avenue facility in late 1955. Effective remediation of the Downey facility was accomplished at that time.

In 2000, The Boeing Company performed a survey verifying that the prior remediation met current Nuclear Regulatory Commission and State of California requirements. Ownership of the Downey facility was then transferred to the City of Downey.

CONTRACTOR: North American Aviation 1948-1955

Listing:

Downey Facility is listed as a Department of Energy (DOE) site under the EEOICPA.

Classes:

All employees of the Department of Energy, its predecessor agencies, and their contractors and subcontractors who worked at the Downey Facility in Los Angeles County, California from January 1, 1948 through December 31, 1955, for a number of work days aggregating at least 250 work days, occurring either solely under this employment or in combination with work days within the parameters established for one or more other classes of employees included in the Special Exposure Cohort.

History:

The Downey Facility is located in Downey, California, and has been involved in the research and development of aircraft since the founding of EMSCO Aircraft Corporation in Downey by E. M. Smith in 1929. Since that time, the manufacturing facility as changed hands several times.

From the early 1950’s to 1964, the Downey facility was officially known as AFP 16 (Air Force Plant 16). Under Air Force contract, the Downey Facility, which was owned by the Vultee Aircraft Division of the Aviation Manufacturing Corporation began to develop a new missile concept called Navaho, which would lead to technology utilized in the space program. The company was also experimenting with two types of processes. One such power source was atomic energy, and in 1952 a small, low-power research reactor was tested and placed into operation in Downey and was the first nuclear reactor built and operated in California.

In the following years, the Downey Facility was involved in manufacturing the prototype for cruise missiles, the development of the X-15 aircraft, and in 1964 was transferred to NASA to work on the space program. Downey worked on the Apollo project and the Columbia, Challenger, Discovery, and Atlantis space shuttles.

By the end of 1999, Downey, now owned by Boeing North American, was closed.

Compensation:

As of 08/2015, the total compensation paid under Parts B and E of the EEOICPA, including medical compensation, for workers suffering from the effects of having worked at Downey Facility is $10,578,423. Click here for a current accounting of compensation paid to former Downey Facility Workers under the EEOICPA.

Downey Facility Workers:

If you or your parent worked at this or any other DOE or AWE facility and became ill, you may be entitled to compensation of up to $400K plus medical benefits from the US Department of Labor. Call EEOICPA Counsel Hugh Stephens at 1-855-EEOICPA (336-4272) or fill out the form to the right, whether your claim has been accepted or denied.

We can help with all OWCP (Federal Workers Compensation) claims, impairments, wage loss and health care. 2495 Main Street, Suite 442 Buffalo, NY.

*NIOSH site Profile:

The Downey facility is on Lakewood Boulevard in Downey, California. AEC-funded activities were performed by Rockwell’s Atomics International Division in a small portion of this large building between 1948 and 1955. AEC activities included mainly paper studies, research and development, and engineering studies. However, these activities also involved the use of a 2-MeV Van de Graaff generator, a small-scale radiochemical laboratory, a neutron counting room, and a construction area with a small 0.5-W teaching reactor. In addition, the AEC funded a 4-W WBNS at the Downey facility.

Startup for the reactor was in April of 1952. The reactor fuel was uranyl sulfate with a sealed polonium and beryllium neutron source; only very small quantities of radioactive material were ever present at the facility. There were 3 Ci of radioactive material present when the reactor was at full power. The WBNS operated at Downey until December 1955. In 1956 it was dismantled and moved to Area IV. Personnel and operations from Downey moved to the Canoga Avenue facility in late 1955.

The major quantity of radioactive material at Downey was canned normal and depleted uranium metal used in the exponential pile. The exponential pile was a system designed to model different fuel/moderator lattice configurations. The behavior of neutron flux in these lattices was measured. The 4-W WBNS was used as a neutron source for the exponential pile. The radioactive material was obtained from a variety of AEC and government contractors. After use it was returned to the source or transferred to the SSFL. The loading dock was the only place where the fuel was stored. All isotopes used at Downey by Rockwell were used for industrial radiography at Building 004, on Clark Avenue. All isotopes were disposed of in the early 1990s.

Effective remediation of the Downey facility was accomplished in 1956. In 2000, Boeing performed a survey verifying that the previous remediation met current NRC and California requirements. Ownership of the Downey facility was then transferred to the City of Downey.

*Source

**The Downey Facility

The Downey Facility on Lakewood Blvd. in the City of Downey, was used by North American Aviation (NAA) to build airplanes during the 1940s and 1950s. It was later used by Rockwell International to build the Space Shuttle. In addition to these aerospace operations, a small portion of the Downey facility was also used for nuclear research from 1948 to 1955. Operations were conducted by the Atomic Energy Research Department (AERD), which later became the Atomics International (AI) Division when operations were moved to the Canoga Facility in late 1955.

AERD was engaged in research and development for controlled release of energy from the atom for the production of electric power. This research and development was then sponsored by the Atomic Energy Commission (AEC).

One of the projects was the design, construction and operation of the first nuclear reactor in California. A source of neutrons was needed for one of the reactor physics projects, so a small aqueous, homogeneous reactor called the Water Boiler Neutron Source (WBNS) was built and put into operation on April 21, 1952. The reactor was operated at power levels up to 4 watts and served as an excellent neutron source for a number of reactor physics programs. It didn’t really boil water, as one might guess from the 4-watt power level, but a small amount of hydrogen and oxygen from decomposition of the water was released from the solution into a tank during operation – hence the designation “water boiler”.

**Source

________________________________________________________________________________

ELECTRO CIRCUITS, INC.

State: California

Location: Pasadena

Time Period: 1952-1953

Facility Type: Atomic Weapons Employer

Facility Description: Electro Circuits used uranium metal (approximately 300 lb.) to conduct tests aimed at determining the usefulness of ultrasonics in the detection of pipe in ingots.

Listing:

Electro Circuits, Inc. is listed as an Atomic Weapons Employer (AWE) site and as a Department of Energy (DOE) site under the EEOICPA.

Electro Circuits, Inc. Workers:

If you or your parent worked at this or any other AWE facility and became ill, you may be entitled to compensation of up to $150K plus medical benefits from the US Department of Labor. Call EEOICPA Counsel Hugh Stephens at 1-855-EEOICPA (336-4272) or fill out the form to the right, even if your claim has been accepted or denied.

We can help with all OWCP (Federal Workers Compensation) claims, impairments, wage loss and health care. 2495 Main Street, Suite 442 Buffalo, NY.

________________________________________________________________________________

GENERAL ATOMICS

Also Known As: GA, Division of General Dynamics, John Jay Hopkins Laboratory for Pure and Applied Science

State: California

Location: La Jolla

Time Period: BE 1959-1967; AWE 1960-1969; Residual Radiation 1970- 1995, 2000; DOE 1996-1999 (remediation)

Facility Type: Atomic Weapons Employer (AWE), Beryllium Vendor (BE), Department of Energy (DOE)

Facility Description:

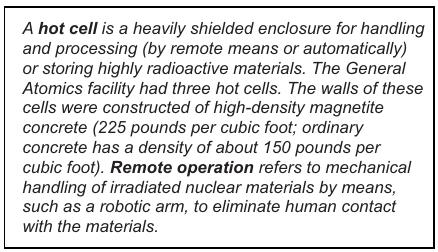

General Atomics was one of a number of private contractors that processed unirradiated scrap for the Atomic Energy Commission in the 1960s. In addition, the Hot Cell Facility was used for numerous post-irradiation examinations of Department fuels, structural materials, reactor dosimetry materials, and instrumentation. The Department- sponsored activities at the General Atomics Hot Cell Facility primarily supported the High Temperature Gas Cooled Reactor and the Reduced Enrichment Research Test Reactor programs. In December 1994, General Atomics notified the Nuclear Regulatory Commission and the State of California Department of Health Services of its intent to cease operations in the Hot Cell Facility.

General Atomics was also the operating contractor for the AEC’s Experimental Beryllium Oxide Reactor (EBOR). General Atomics manufactured EBOR fuel elements (UO2-BeO) on site and examined them in the site’s hot cell.

During the period of residual contamination, as designated by the National Institute for Occupational Safety and Health and as noted in the dates above, employees of subsequent owners and operators of this facility are also covered under the Energy Employees Occupational Illness Compensation Program Act.

Listing:

General Atomics is listed as a Department of Energy (DOE) site from 1960 – 1969, as Beryllium Employer (BE) site from 1959-1967 , and as an Atomic Weapons Employer (AWE) from 1960 -1995.

The Special Exposure Cohort dates for General Atomics are from 1960 -1969

Classes:

Atomic Weapons Employer (AWE) employees who were monitored or should have been monitored for exposure to ionizing radiation while working at the General Atomics facility in La Jolla, California at the following locations: Science Laboratories A, B, and C (Building 2); Experimental Building (Building 9); Maintenance (Building 10); Service Building (Building 11); Buildings 21 and 22; Hot Cell Facility (Building 23); Waste Yard (Buildings 25 and 26); Experimental Area (Buildings 27 and 27-1); LINAC Complex (Building 30); HTGR-TCF (Building 31); Fusion Building (Building 33); Fusion Doublet III (Building 34); SV-A (Building 37); SV-B (Building 39); and SV-D (no building number) for a number of work days aggregating at least 250 work days from January 1, 1960, through December 31, 1969, or in combination with work days within the parameters established for one or more other classes of employees in the SEC.

Compensation:

As of 08/2015, the total compensation paid under Parts B and E of the EEOICPA, including medical compensation, for workers suffering from the effects of having worked at General Atomics is $20,258,489. Click here for a current accounting of compensation paid to former General Atomics Workers under the EEOICPA.

General Atomics Workers:

If you or your parent worked at this or any other DOE or AWE facility and became ill, you may be entitled to compensation of up to $400K plus medical benefits from the US Department of Labor. Call EEOICPA Counsel Hugh Stephens at 1-855-EEOICPA (336-4272) or fill out the form to the right, even if your claim has been accepted or denied.

We can help with all OWCP (Federal Workers Compensation) claims, impairments, wage loss and health care. 2495 Main Street, Suite 442 Buffalo, NY.

Job Titles and/or Job Duties: Potentially worked in the locations–

- Building 2 (Science laboratories A, B, and C)

- Building 9 (Experimental Building)

- Building 10 (Maintenance)

- Building 11 (Service Building)

- Building 21

- Building 22

- Building 23 (Hot Cell Facility)

- Building 25

- Building 26

- Building 27 (Experimental Area Building #1)

- Building 27-1 (Experimental Area Building #1)

- Building 30 (LINAC Complex)

- Building 31 (HTGR-TCF)

- Building 33 (Fusion Building)

- Building 34 (Fusion Doublet III)

- Building 37 (SV-A)

- Building 39 (SV-B)

- SV-D

Period of Employment: January 1, 1960, through December 31, 1969

History:

In 1955, General Atomics (GA) was formed as a division of General Dynamics in San Diego, California. Its purpose was to develop beneficial technologies using nuclear energy. Since that time, GA has carried out research dealing with the nuclear fuel cycle, electromagnetic systems, remotely operated surveillance aircraft, and other technologies.

NIOSH site profile:

GENERAL SITE DESCRIPTION AND OPERATIONAL HISTORY

General Dynamics Corporation acquired property in La Jolla, California, in 1956 where the John J.

Hopkins Laboratory for Pure & Applied Science – later named the General Atomic Division of General Dynamics facility – was built. The information that follows applies to a period of AEC radiological operations at GA in La Jolla, California, from January 1, 1960, to December 31, 1969. This document assumes that the residual contamination period was from January 1, 1970, through December 31, 1995. DOE remediation activities are listed by the DOE Office of Worker Advocacy and are assumed to run from January 1, 1996, through December 31, 1999. Although beryllium exposure is not considered in this part of the program, it is noted that the covered period for beryllium began a year before the period for radiation exposure.

The GA source term includes depleted, normal, and highly enriched uranium (typically greater than

20% and up to 93.5% 235U by mass) in the form of scrap and reactor fuel both in a fresh form and in an irradiated form that includes uranium as well as activation and fission products. Thorium was used in fuel fabrication work. Plutonium work also occurred on the site. Four linear accelerators (LINACs) and several nuclear reactors were also available. Sealed sources were used for instrument calibrations and other work. Byproduct materials (atomic numbers 3 to 83) and tritium were also used.

According to a company pamphlet, General Dynamics Corporation established General Atomic

Division on July 18, 1955, in San Diego, California, to develop commercial applications for nuclear technology. GA was also known as John Jay Hopkins Laboratory for Pure and Applied Science; Gulf General Atomic; Gulf General Atomics Company; Gulf Energy & Environmental Systems; and GA Technologies. At one point they were held in partnership between Gulf Oil Corporation and Scallop Nuclear, and the partnership was known as Valley Pin Associates.

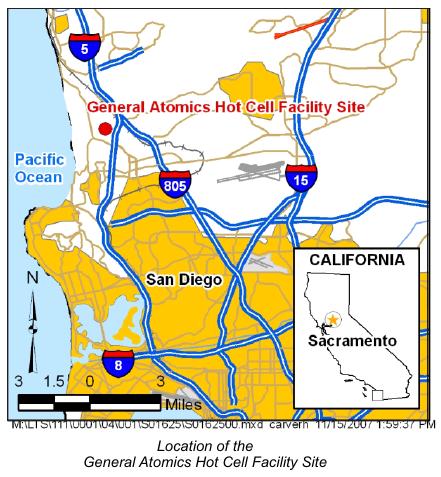

SITE DESCRIPTION

The current GA main site, a 60-acre complex on Torrey Pines Mesa in La Jolla, California (GA 1998), is the facility location that is covered by EEOICPA. The main site is approximately 300 ft above sea level, 1 mi from the Pacific Ocean, and 13 mi northwest of downtown San Diego. The GA site is in the center of Torrey Mesa Science Center, a 304-acre industrial park. The majority of GA buildings are on top of the mesa, but some work [e.g., at the Fuel Fabrication Facility (Building 37)] and the Fusion Energy Facility (also known as DIII-D National Fusion Facility) occurred (and some still occurs) at the base of the mesa to the east of the central set of site buildings.

Radiological work at facilities on the mesa included the HCF (Building 23) activities; Training, Research, Isotopes, General Atomics (TRIGA) reactor facilities activities; LINAC work; and neutron studies. In addition, research and development, including metallurgical and chemistry work, was occurring in the Science Laboratory and Experimental Buildings. The Fuel Fabrication Facility and the HCF were both in operation by the end of the 1950s. The HCF included support for high-temperature gas-cooled reactor (HTGR) and TRIGA reactor fuel research and development. Beginning in October 1966, a Plutonium Laboratory that was equipped with gloveboxes and high-efficiency particulate air (HEPA) filtration exhaust systems was activated for the first time in the HCF (Gurren 1966a).

General Dynamics/Convair work at the Kearny Mesa Site in San Diego, California, which is not listed as a covered facility by the DOE Office of Worker Advocacy, is not specifically considered in this site profile, but is mentioned because

of the possibility that dosimetry records for some workers might include exposures from both the San Diego site and the La Jolla site. Work on the Experimental Beryllium Oxide Reactor (EBOR) project might have occurred both in California and at the Idaho National Laboratory, and dosimetry records from both sites might be needed to reconstruct dose for these workers.

GA possessed and used radioactive materials under several licenses and its radiological programs

were regulated by the Federal Government and the State of California.

*Site Description and History:

The former General Atomics Hot Cell Facility was constructed in 1959 and operated until 1991. The site encompassed approximately 7,400 square feet of laboratory and remote operations cells. Licensed operations at the facility included receipt, handling, and shipment of radioactive materials; remote handling, examination, and storage of previously irradiated nuclear fuel materials; pilot-scale tritium extraction operations; and development, fabrication, and inspection of uranium oxide–beryllium oxide fuel materials. General Atomics performed most of the work for the federal government.

The General Atomics Hot Cell Facility was located in a 60-acre complex 13 miles northwest of downtown San Diego, 1 mile inland from the Pacific Ocean, and approximately 300 feet above sea level. The General Atomics site is in the center of Torrey Mesa Science Center, a 304-acre industrial park. No groundwater wells are at or near the Hot Cell Facility. Regional hydrogeologic data indicate that the uppermost aquifer is about 300 feet below ground surface at the site.

Because of a significant decline in the projected use of the facility, a decline in nuclear fission research, and increasing industrial development surrounding the General Atomics site in the early 1990s, General Atomics’ management decided to decontaminate and decommission the Hot Cell Facility and remediate the associated yard area. General Atomics requested assistance from the U.S. Department of Energy (DOE).

Discussions between DOE and General Atomics led to an agreed cost-sharing and no-fee arrangement for the decontamination and site remediation prorated on the basis of facility usage by the federal government. After an examination of records, the cost shares were calculated to be 76 percent federal work and 24 percent commercial work. Work began in 1993 to inventory the material and equipment in the facility for disposal, dispose of legacy waste from previous contracts, determine the magnitude and extent of contamination, and prepare a decontamination and decommissioning plan and supporting documents.

The main source of radioactive contaminants at the facility were nuclear materials and fission/activation products in previously irradiated fuel materials. The facility also had lesser amounts of nonradioactive hazardous waste consisting of asbestos and lead. The total activity of all radionuclides in the irradiated fuel materials, decayed to a reference date of September 30, 2003, was about 2,660 curies.

Wastes from the Hot Cell Facility dismantlement and subsequent site cleanup activities consisted of removing radioactively contaminated soil, asphalt, concrete rubble, construction material debris, and facility equipment.

Selected materials and equipment were removed from the facility in 1995 and salvaged for reuse or packaged for disposal. Contaminated systems were shipped to a low-level radioactive waste disposal facility. Decontamination of the hot cells used a variety of techniques; the predominant one was abrasive cleaning of the concrete surfaces. Interiors of the hot cells were cleaned using remotely operated cleaning methods followed by abrasive cleaning. When all loose contami- nation had been removed and the cells cleaned, the building was surveyed for radioactivity and dismantled. Material with no radioactive contamination was disposed of as “clean” waste, and material with contamination that could not be removed was shipped off site for burial as contaminated low-level radioactive waste. Buried items, including wells, hot drain lines, and high-efficiency air particulate ducting, were excavated and shipped off site for disposal. Remediation of the yard area was followed by radiological surveys and additional remediation until release criteria were met in all areas. The Hot Cell Facility site was released for unrestricted use by the U.S. Nuclear Regulatory Commission (NRC) in July 2000 and by the State of California Department of Health Services in August 2000.

DOE-owned legacy irradiated fuel materials from the site were shipped to the Idaho National Engineering and Environmental Laboratory at Idaho Falls, Idaho, for interim storage. Of the radioactive waste shipped off site for permanent disposal, 94,438 cubic feet went to the Hanford, Washington, facility; 60,524 cubic feet went to Envirocare, LLC, near Salt Lake City, Utah; 57,659 cubic feet went to the Nevada Test Site; and 486 cubic feet was shipped to various smaller facilities.

*Source

________________________________________________________________________________

HIGH ENERGY RATE FORGING (HERF) FACILITY

State: California

Location: Oxnard

Time Period: 1984-1997

Facility Type: Department of Energy

Facility Description: The Department of Energy purchased this facility in 1984 for the purpose of producing forgings for weapons parts. It consists of 13.75 acres and 7 buildings. The DOE Rocky Flats Plant managed the forging process and produced forgings at this location through 1995. In 1994, DOE decided to close the facility upon completion of its defense-related mission in 1996. The facility was sold on June 30, 1997.

CONTRACTORS: Kaiser Hill (1995-1997); EG&G Rocky Flats, Inc. (1989-1995); Rockwell International (1975-1989)

Listing:

High Energy Rate Forging (HERF) Facility is listed as an Atomic Weapons Employer (AWE) site and as a Department of Energy (DOE) site under the EEOICPA.

High Energy Rate Forging (HERF) Facility Workers:

If you or your parent worked at this or any other AWE facility and became ill, you may be entitled to compensation of up to $150K plus medical benefits from the US Department of Labor. Call EEOICPA Counsel Hugh Stephens at 1-855-EEOICPA (336-4272) or fill out the form to the right, even if your claim has been accepted or denied.

________________________________________________________________________________

HUNTER DOUGLAS ALUMINUM CORP.

Also Known As: Hunter Douglas Aluminum Plant, Bridgeport Brass

State: California

Location: Riverside

Time Period: 1959-1963

Facility Type: Atomic Weapons Employer

Facility Description: In 1959, Hunter Douglas Aluminum extruded approximately 1600 pounds of solid uranium stock for National Lead Company of Ohio (Fernald). In a subsequent subcontract, the company fabricated uranium-zirconium billets for the GE Evendale Plant.

Listing:

Hunter Douglas Aluminum Corp. is listed as an Atomic Weapons Employer (AWE) site under the EEOICPA.

Compensation:

As of 04/05/2015, the total compensation paid under Part B of the EEOICPA, including medical compensation, for workers suffering from the effects of having worked at Hunter Douglas Aluminum Corp. is $1,890. Click here for a current accounting of compensation paid to former Hunter Douglas Workers under the EEOICPA.

Hunter Douglas Aluminum Corp. Workers:

If you or your parent worked at this or any other AWE facility and became ill, you may be entitled to compensation of up to $150K plus medical benefits from the US Department of Labor. Call EEOICPA Counsel Hugh Stephens at 1-855-EEOICPA (336-4272) or fill out the form to the right, even if your claim has been accepted or denied.

We can help with all OWCP (Federal Workers Compensation) claims, impairments, wage loss and health care. 2495 Main Street, Suite 442 Buffalo, NY.

________________________________________________________________________________

LABORATORY OF BIOMEDICAL AND ENVIRONMENTAL SCIENCES

State: California

Location: Los Angeles

Time Period: 1947-present

Facility Type: Department of Energy

Facility Description: The Laboratory of Biomedical and Environmental Sciences (LBES) was established in 1947 on the campus of the University of California, Los Angeles, to provide biomedical and environmental support to nuclear testing activities. Today’s programs are in three areas: nuclear medicine, where the study of positron emission tomography (PET) is applied to medical problems; biomolecular and cellular sciences, which involves factors influencing gene expression, particularly with reference to early molecular events in cancer induction; and environmental biology, which focuses on the basic physiology of plants in arid ecosystems.

Listing:

Laboratory of Biomedical and Environmental Sciences is listed as a Department of Energy (DOE) site under the EEOICPA.

Laboratory of Biomedical and Environmental Sciences Workers:

If you or your parent worked at this or any other DOE or AWE facility and became ill, you may be entitled to compensation of up to $400K plus medical benefits from the US Department of Labor. Call EEOICPA Counsel Hugh Stephens at 1-855-EEOICPA (336-4272) or fill out the form to the right, even if your claim has been accepted or denied.

We can help with all OWCP (Federal Workers Compensation) claims, impairments, wage loss and health care. 2495 Main Street, Suite 442 Buffalo, NY.

________________________________________________________________________________

LEBOW

State: California

Location: Goleta

Time Period: 1977-2002

Facility Type: Beryllium Vendor

Facility Description: The Lebow Company produces ultra-thin metal foils for Sandia National Laboratory, California, some of which contain beryllium.

Listing:

Lebow is listed as a Beryllium Vendor (BE) under the EEOICPA.

Lebow Workers:

If you or your parent worked at this or any other AWE facility and became ill, you may be entitled to compensation of up to $150K plus medical benefits from the US Department of Labor. Call EEOICPA Counsel Hugh Stephens at 1-855-EEOICPA (336-4272) or fill out the form to the right, even if your claim has been accepted or denied.

We can help with all OWCP (Federal Workers Compensation) claims, impairments, wage loss and health care. 2495 Main Street, Suite 442 Buffalo, NY.

________________________________________________________________________________

PHILCO-FORD CORPORATION

Also Known As: Ford Aeronutronic

State: California

Location: Newport Beach

Time Period: 1967-1972

Facility Type: Beryllium Vendor

Facility Description: The Aeronutronic Division of the Philco-Ford Corporation engaged in research on beryllium manufacturing techniques for the AEC between 1967 and 1972. The overriding goal of the program was to demonstrate the feasibility of shear spinning technology for beryllium production. The production process involved drilling and grinding of beryllium cones.

Listing:

Philco-Ford Corporation is listed as a Beryllium Vendor (BE) under the EEOICPA.

Compensation:

As of 05/03/2015, the total compensation paid under Part B of the EEOICPA, including medical compensation, for workers suffering from the effects of having worked at Philco-Ford Corporation is $150,000. Click here for a current accounting of compensation paid to former Philco-ford Workers under the EEOICPA.

Philco-Ford Corporation Workers:

If you or your parent worked at this or any other AWE facility and became ill, you may be entitled to compensation of up to $150K plus medical benefits from the US Department of Labor. Call EEOICPA Counsel Hugh Stephens at 1-855-EEOICPA (336-4272) or fill out the form to the right, even if your claim has been accepted or denied.

We can help with all OWCP (Federal Workers Compensation) claims, impairments, wage loss and health care. 2495 Main Street, Suite 442 Buffalo, NY.