The EEOICPA was passed in 2000. It provides compensation to workers who became ill as a result of their employment manufacturing nuclear weapons in the USA, as well as their spouses, children, and grandchildren. B&T Metals EEOICPA coverage is available for qualified former Workers and their families.

Are you eligible for compensation? If you or a family member worked at this or another AWE/DOE facility and became ill, you may be entitled to compensation of up to $400K plus medical benefits. Call EEOICPA Counsel Hugh Stephens at 1-855-548-4494 or fill out our free claim evaluation, We can help even if you’ve already filed, even if your claim was denied!

Here, we have compiled publicly available information and documentation about the facilities covered by the Act to clarify how their activities relate to the Energy Employees Occupational Illness Compensation Program Act.

B&T Metals

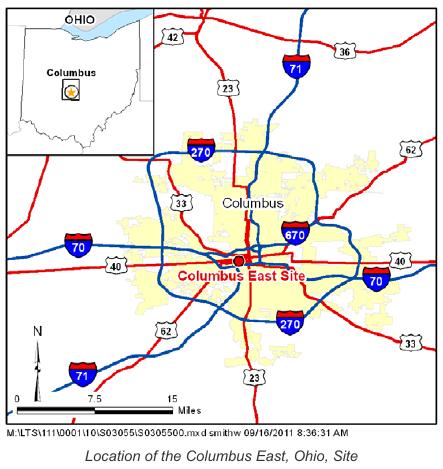

State: Ohio

Location: Columbus

Time Period: AWE 1943; Residual Radiation 1944-1995; DOE 1996 (remediation)

Facility Type: Atomic Weapons Employer, Department of Energy

Facility Description: During the early stages of nuclear weapons production, uranium reactor fuel was produced by a variety of metallurgical techniques including extrusion, casting, and machining.

In February 1943, DuPont, acting as an agent of the Manhattan Engineer District, contracted B&T Metals to extrude rods from uranium metal billets for the Hanford reactor in Washington State. B&T Metals extruded an estimated 50 tons of uranium between March 1943 and August 1943.

Environmental cleanup under the Formerly Utilized Site Remediation Program (FUSRAP) was conducted in 1996. This work was performed by employees of SunPro as subcontractors to Bechtel National Inc., the company that held the umbrella contract for DOE site environmental remediation. This site’s remedial action was certified complete in 2001.

During the period of residual contamination, as designated by the National Institute for Occupational Safety and Health and as noted in the dates above, employees of subsequent owners and operators of this facility are alsocovered under the Energy Employees Occupational Illness Compensation Program Act.

Listing:

B&T Metals is listed as an Atomic Weapons Employer (AWE) site and a Department of Energy (DOE) site under the EEOICPA.

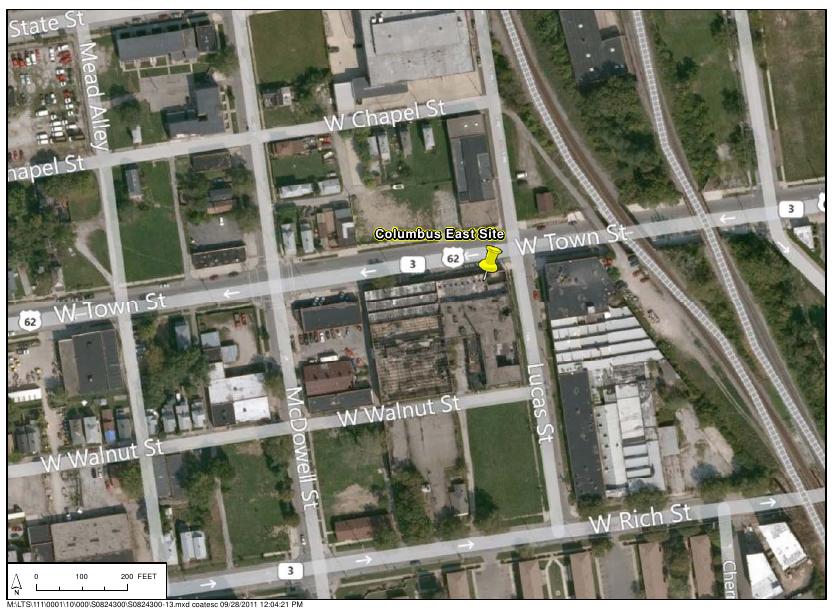

*Department of Energy Formerly Utilized Sites Remedial Action Program (FUSRAP) – Central Ohio – B & T Metals (Columbus East) , Columbus, Ohio:

The former B & T Metals is located at 425 West Town Street on the southwest side of Columbus, Ohio. The buildings and property cover most of a city block. The site consists of three buildings: the main office, a storage building, and an extrusion building that did not exist at the time of the Manhattan Engineer District activities during the 1940s. The work performed for the Manhattan Engineer District occurred in the northwest corner of the main office building.

In February 1943, the DuPont Company, acting as an agent of the Manhattan Engineer District, contracted with B & T Metals to extrude rods from uranium metal billets for the Hanford, Washington reactor. B & T Metals extruded an estimated 50 tons of uranium. In 1988 and 1989, preliminary radiological assessments identified higher than normal concentrations of uranium in dust on building support beams, in several floor, sump and drain locations inside the main office building, and in several outdoor locations. B&T Metals was designated for remedial action under the Formerly Utilized Sites Remedial Action Program (FUSRAP) in October 1992 by the U.S. Department of Energy (DOE).

A DOE contractor decontaminated the northwest corner of the main building, rain gutters, three exterior manholes, and exterior soil adjacent to an electrical substation. In the spring of 1996, a post remedial action survey and verification of residual uranium in soil at B&T Metals was completed by the Oak Ridge National Laboratory (operated by Martin Marietta Energy Systems, Inc.) using a site-specific derivation of the remedial action guidelines (i.e., release criteria of 35 pCi/gram).

FUSRAP cleanups reached the half-way mark with the June 11, 1996 completion of the B&T Metals site. Once the site was released by DOE for use without radiological restrictions, the notice of certification of radiological condition was published in the Federal Register on June 26, 2001. The Ohio Department of Health (ODH), Bureau of Radiation Protection, provided health physics oversight during the decontamination process and as the radiation control agency ensured that the facility was decontaminated to free release levels and no longer serves as a potential radiological health and safety concern.

*Source

Compensation:

As of 03/15/2015, the total compensation paid under Parts B and E of the EEOICPA, including medical compensation, for workers suffering from the effects of having worked at B&T Metals is $0.

B&T Metals Workers:

If you or your parent worked at this or any other AWE facility and became ill, you may be entitled to compensation of up to $150K plus medical benefits from the US Department of Labor. Call EEOICPA Counsel Hugh Stephens at 1-855-EEOICPA (336-4272) or fill out the form to the right, whether or not you have already filed a claim and even if your claim has been accepted or denied.

We can help with all OWCP (Federal Workers Compensation) claims, impairments, wage loss and health care. 2495 Main Street, Suite 442 Buffalo, NY.

**Site Description and History:

The Columbus East, Ohio, Site (formerly the B&T Metals site) is located at 425 West Town Street in southwest Columbus, Ohio. The site consists of a main building, a storage building, and an aluminum extrusion building and covers most of a city block.

From March through August 1943, B&T Metals extruded uranium fuel rods from uranium metal billets (bars or ingots of uranium formed as an intermediate product) under contract to E.I. du Pont de Nemours and Company (DuPont). The rods were manufactured in support of Manhattan Engineer District (MED) operations and were destined for use as fuel in the Hanford, Washington, nuclear reactor. It is estimated that more than 50 tons of uranium were extruded.

The work performed for MED occurred in the northwest corner of the main building, the largest of the three site structures. Upon completion of the extrusion project, representatives of MED and DuPont visually inspected the site to verify that all sweepings, turnings, solid scrap, and other remnants of the operation had been shipped off site.

In 1988 and 1989 Oak Ridge National Laboratory, a U.S. Department of Energy (DOE) facility in Oak Ridge, Tennessee, conducted initial screening surveys to evaluate the radiological conditions at the site. The surveys identified elevated concentrations of uranium inside the main building in several floor, sump, and drain locations and in dust on building support beams. Elevated gamma radiation was also detected in soil samples taken from the outdoor area where process fluids or shavings from the MED activities reportedly were disposed of. The site was recommended for remediation under the Formerly Utilized Sites Remedial Action Program (FUSRAP). Decontamination of the facility was conducted from March through June 1996 under the direction of Bechtel National, Inc., the project management contractor for FUSRAP.

***

***Source

***Source