The General Electric Company, also known as GE Evendale, is a facility that started out building aircraft engines. During this time, the GE Evendale facility was also being utilized so that a group of workers could experiment with a variety of radioactive materials, including uranium and thorium. Due to the lack of stringent regulations in terms of worker safety during this time, employees, scientists, and contractors may have been exposed to harmful materials or chemicals resulting in an increase in cancer diagnoses.

The EEOICPA was passed in 2000 and provides compensation to workers who became ill as a result of their employment at GE Evendale. EEOICPA coverage is available for qualified former workers and their families.

Here, we have compiled publicly available information and documentation about the facilities covered by the Act to clarify how their activities relate to the Energy Employees Occupational Illness Compensation Program Act.

General Electric Company (Ohio)

Also Known As: GE Evendale, GE Cincinnati, GE Lockland, Air Force Plant 36

State: Ohio

Location: Cincinnati/Evendale

Time Period: BE 1951-1970; DOE 1961-June 30,1970

Facility Type: Beryllium Vendor Department of Energy

Facility Description: The Evendale Plant’s major mission is to build aircraft engines. The AEC used this facility to work with a variety of radioactive materials, including uranium and thorium. This facility was also involved in the refining or fabrication of beryllium or beryllium oxide.

Listing:

General Electric Company is listed as a Department of Energy (DOE) site under the EEOICPA.

Special Exposure Cohort(SEC) Classes:

All employees of the Department of Energy, its predecessor agencies, and their contractors and subcontractors who worked at General Electric Co. in Evendale, Ohio, from January 1, 1961 through June 30, 1970, for a number of work days aggregating at least 250 work days, occurring either solely under this employment or in combination with work days within the parameters established for one or more other classes of employees included in the Special Exposure Cohort.

Compensation:

As of 01/08/2023, the total compensation paid under Parts B and E of the EEOICPA, including medical compensation, for workers suffering from the effects of having worked at the General Electric Company (Ohio) is $169,112,260. Click here for a current accounting of compensation paid to former General Electric Company (Ohio) Workers under the EEOICPA.

General Electric Company (Ohio) Workers:

If you or your parent worked at this or any other DOE or AWE facility and became ill, you may be entitled to compensation of up to $400K plus medical benefits from the US Department of Labor. Call EEOICPA Counsel Hugh Stephens at 1-855-EEOICPA (336-4272) or fill out the form to the right, whether or not you have already filed a claim and even if your claim has been accepted or denied.

We can help with all OWCP (Federal Workers Compensation) claims, impairments, wage loss and health care. 2495 Main Street, Suite 442 Buffalo, NY.

History:

Department of Defense Formerly Used Defense Sites (FUDS) Southwest Ohio Air Force Plant 36

Site Number: G05OH0991

This 68 acre site is located in Evendale, Ohio, Hamilton County, Sycamore Township, near Cincinnati. The United States Air Force (AF) acquired this property from the Reconstruction Finance Company by 2 deeds. The first of these deeds was in October 1948, and the second was in August 1949. The United States AF owned the Air Force Plant 36 property from October 1948 to June 1989. During this time the mission of the plant was the assembly and testing of aircraft engines. In 1989, the property was quitclaimed to General Electric. The former Air Force Plant had 21 underground storage tanks (removed in 1987) that were used for the storage of gasoline, kerosene, diesel fuel, jet fuel, waste fuel, and process water. The site also has a fuel farm consisting of four 1,000,000-gallon aboveground storage tanks and fuel distribution system. The site had a chip loading area which contained scrap metal and metal shavings from aluminum, magnesium, nickel, chromium, and titanium alloys. Concrete floor drains, storm water sewers, and drainage ditches on the site have been subjected to wash water, oily wastewater runoff, metals, and petroleum. Contaminants known or alleged to be found in ground water,surface water, soils, and the aquifer include TPH, TCE, BTEX, acetone, trichloroethene, PCB, tetrachloroethene, aluminum, magnesium, nickel, chromium and titanium. The site is proposed for Hazardous, Toxic, and Radioactive Waste (HTRW) and Resource Conservation Recovery Act (RCRA)investigations. The HTRW projects are proposed for hydrogeologic study, ground water monitoring, and investigation of former underground storage tank (UST) sites. The RCRA facilities are proposed for investigation of the storm drainage system, the sanitary sewer, the oil-water separators, and the chip stockpile and loading area, as well as a study of the confining clay layer between the upper and lower (water supply) aquifers. These investigations are ongoing.

OHIO DEPARTMENT OF HEALTH BUREAU OF RADIATION PROTECTION

Historical Radiological Sites in Ohio Comprehensive List

General Electric Co.

a.k.a. GE Evendale, GE Cincinnati, GE Lockland , Air Force Plant 36

Cincinnati, Ohio

1951 – 1970

-Documentation reviewed indicates that Aircraft Nuclear Propulsion (ANP) work reportedly began at this General Electric facility in 1951 as a joint Air Force/AEC program, which subsequently ended in 1961.

-Performed work under AEC license involving radioactive material between 1961 and 1970.

-The Evendale Plant’s major mission is to build aircraft engines. The AEC used this facility towork with a variety of radioactive materials, including uranium and thorium. This facility was also involved in the refining or fabrication of beryllium or beryllium oxide.

Use of radioactive materials reportedly continued at this facility for other AEC related work until 1973.

* General Electric Co. (Ohio) – SEC Petition Evaluation Report:

Operations Description:

General Electric’s Aircraft Nuclear Propulsion (ANP) Project began in 1951 at the facility in Evendale, Ohio. The ANP work was performed in a facility known as Air Force Plant 36, a 68-acre portion of the larger General Electric Aircraft Engine Plant (EPA, 2008). The ANP Project was terminated in 1961; however, the use of radioactive materials continued under other Atomic Energy Commission (AEC) contracts (Murphy, 1988, p. 9). In 1961, GE-Ohio continued as a prime contractor to the AEC for development of high-temperature fuel elements and reactor materials (Review, 1979, pdf p. 4). From 1961 through June 30, 1970, the AEC contract work occupied buildings C and D and certain other smaller auxiliary structures, under a use permit from the Air Force. Custody of the facilities was returned to the Air Force on June 30, 1970 (General Electric, 1974a).

Information available to NIOSH regarding the size of the radiological workforce at GE-Ohio is limited. In 1959, during the ANP Project, approximately 3000 people were employed on the ANP project, approximately 600 of which were scientific and engineering personnel (General Electric, 1974b, pdf pp. 11-13). Indications of radiological workforce size during the covered 1961-1970 period include the following:

An April 1961 newspaper article states: In practical terms [the cancellation of the ANP project] means that Evendale’s work force will be reduced from 2300 to 375 (POPSEE Sketches, 1991, pdf p. 7)

A July 2010 discussion with former GE-Ohio employees indicates that there were between 300 and 350 workers during the 1961 to 1970 time frame. (Outreach Meeting Minutes, 2010)

AEC operations at GE-Ohio during the Department of Energy (DOE) operations period from January 1, 1961 through June 30, 1970 included:

- testing fuel element materials and high-temperature reactor materials (Rice, 1966, pdf p. 110);

- testing the effects of radiation on refractory metals and alloys (Rice, 1966, pdf p. 110);

- examining radiation effects in beryllium oxide (Rice, 1966, pdf p. 110);

- examining fission product transport processes in reactor fuels (Rice, 1966, pdf p. 110);

- testing the effects on clad uranium-oxide fuels in meltdown environments (Rice, 1966, pdf p. 110);

- developing a process for densification of thoria (Herries, 1966, pdf p. 5); and

- calcination of thorium-oxide in high-temperature furnaces (Rennich, 1965, pdf p. 53).

NIOSH has been unable to collect detailed data describing the processes or equipment associated with the operations listed above. Much of the operations and monitoring data obtained by NIOSH are relevant only to the ANP Project years at GE-Ohio, prior to the covered period under evaluation in this report. NIOSH data capture efforts also failed to produce detailed source term information related to DOE/AEC operations at GE-Ohio during the 1961-through-1970 period. Review of the available data indicates the onsite existence of thorium and fission product residues (Karl, 1969). The potential for uranium and thorium exposures is also evidenced by the inclusion of elemental uranium, enriched uranium, and thorium in the GE-Ohio bioassay program through the 1960s (Boback, 1965; General Electric, 1964; General Electric, 1967).

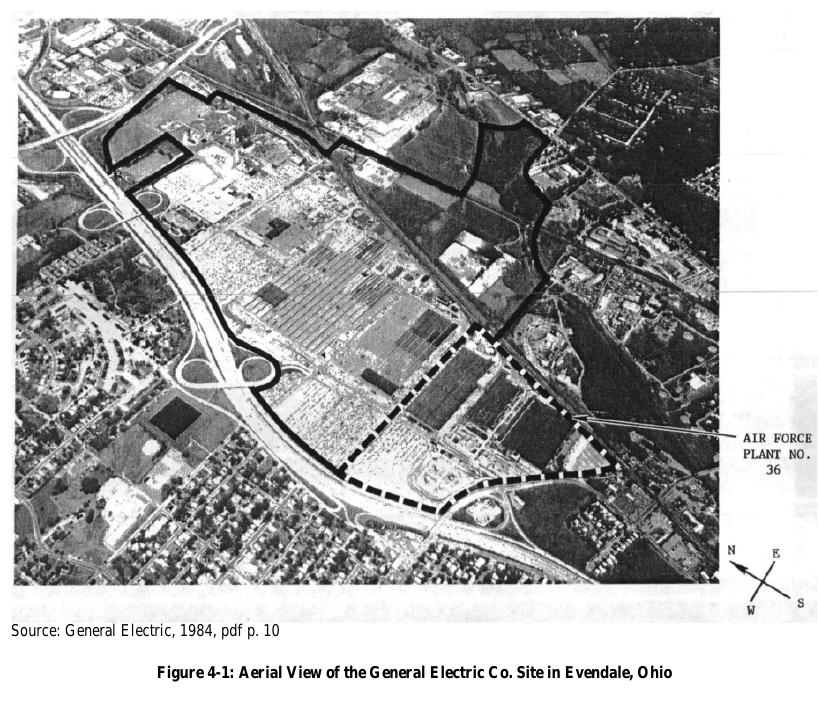

Figure 4-1 provides an aerial photo of the General Electric Co. site in Evendale, Ohio, with the Air Force Plant No. 36 boundary delineated by the dashed line.

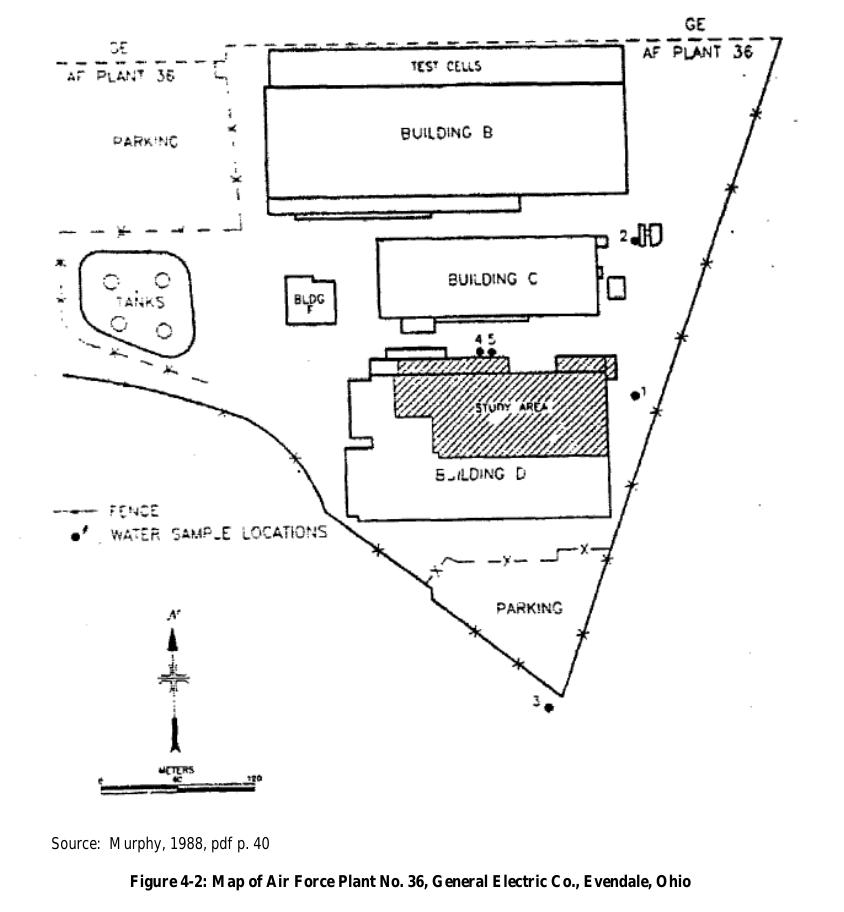

Figure 4-2 shows a more close-up drawing of the Air Force Plant No. 36 footprint.

Building C

Building C, measuring approximately 660 x 280 feet, was built circa 1941. In 1956, additional space was needed to support the ANP operations in Building D; 42% of Building C was allocated and henceforth called “C-West” (General Electric, 1984, pdf p. 9). Between 1961 and 1968, Building C-West was used for fuel element production in conjunction with AEC reactor development programs (General Electric, 1984, pdf p. 15). Beginning in 1967, Room 120 of Building C-West was used to calcine high-purity thoria (ThO 2) for the thermal breeder reactor program. By June 1984, Building C-West was decontaminated to levels below the contemporaneous NRC guideline levels for unrestricted use (General Electric, 1984, pdf p. 66).

Building D

Building D, measuring approximately 680 x 450 feet, was built in 1943 as an aluminum foundry (Review, 1979, pdf p. 11). In 1951, Building D was chosen as the operational laboratory building for the ANP operation (Review, 1979). The main Laboratory area is divided into six blocks of alternating rows of laboratories or rooms. Other support facilities were located west of the Laboratory area. A high bay area was located along the entire length of the north side of Building D. The east portion of the high bay in the Laboratory area housed the Radioactive Materials Laboratory (three hot cells), additional laboratories, central air conditioning and exhaust facilities, and the Nuclear Experimental Area (Thorium Inventory, 1973-1996, pdf p. 8). Sources of laboratory alpha contamination were natural uranium, depleted uranium, 93% enriched uranium, and natural thorium (Thorium Inventory, 1973-1996). Sources of beta-gamma contamination included fission products from irradiated uranium fuel elements in laboratory areas, such as the Radioactive Materials Laboratory; L4-8 (Metallurgical Warm Cell); and Ll-6/Ll-8 (Radiochemistry Warm Cell) (Thorium Inventory, 1973-1996). Decontamination of Building D was completed in 1987 (Thorium Inventory, 1973-1996, pdf p. 17; Hoffer, 1987; Murphy, 1988).

Radioactive Waste Storage Area

The Radioactive Waste Storage facilities were built in 1957 to upgrade the centralized storage and control of radioactive waste prior to shipment to an approved burial site (General Electric, 1986a, pdf p. 10). These facilities were located on the north end of Building D, and consisted of a fenced concrete storage pad on the west adjacent to a decontamination building in the middle, and a clean drum storage area east of the building (Murphy, 1988, pdf p. 17; General Electric, 1986a). The heated building was primarily used for storage of liquid wastes. The west pad was an open area for storage of 55-gallon drums filled with contaminated wastes. On a few occasions (dates unknown to NIOSH), the concrete floor inside the building was contaminated by thorium liquid leakage from the drums (General Electric, 1986a). Decontamination of the Radioactive Waste Storage Area was completed in 1986 (General Electric, 1986a).

*Source

DOCUMENTS:

NIOSH Special Exposure Cohort (SEC) Petition Evaluation Reports

Petition 161 (Jan 1, 1961 to Jun 30, 1970)

SEC Petition Evaluation Report, Petition SEC-00161, Rev #: 1

Report Submittal Date: April 28, 2011

SEC Petition Evaluation Report, Petition SEC-00161, Rev #: 0

Report Submittal Date: January 20, 2010