The EEOICPA was passed in 2000. It provides compensation to workers who became ill as a result of their employment manufacturing nuclear weapons in the USA, as well as their spouses, children, and grandchildren. Combustion Engineering EEOICPA coverage is available for qualified former Workers and their families.

Are you eligible for compensation? If you or a family member worked at this or another AWE facility and became ill, you may be entitled to compensation of up to $150K plus medical benefits. Call EEOICPA Counsel Hugh Stephens at 1-855-548-4494 or fill out our free claim evaluation, We can help even if you’ve already filed, even if your claim was denied!

Here, we have compiled publicly available information and documentation about the facilities covered by the Act to clarify how their activities relate to the Energy Employees Occupational Illness Compensation Program Act.

Combustion Engineering

Also Known As: Asea Brown Boveri

State: Connecticut

Location: Windsor

Time Period: AWE 1965-1972; Residual Radiation 1973-October 2009

Facility Type: Atomic Weapons Employer

Facility Description:

Combustion Engineering (CE) sent shipments of uranium to Fernald between 1965 and 1972 for use in the nuclear weapons production process. It is because of these shipments that this site qualifies as an Atomic Weapons Employer for these years. Combustion Engineering performed substantial work for the Atomic Energy Commission in other years as well, but this work is not covered under EEOICPA because it was either non-nuclear or was not related to weapons production. Starting in the 1940s, this initial work at the site involved non-nuclear components. In 1955, CE began to use highly enriched uranium for its work in supporting the Naval Reactors Program. In the 1960s, CE obtained a license to fabricate fuel elements for power reactors.Although this site was designated as part of the Formerly Utilized Site Remediation Action Program (FUSRAP) in 1994, no work under this program was ever performed on site.

During the period of residual contamination, as designated by the National Institute for Occupational Safety and Health and as noted in the dates above, employees of subsequent owners and operators of this facility are also covered under the Energy Employees Occupational Illness Compensation Program Act.

Listing:

Combustion Engineering is listed as an Atomic Weapons Employer (AWE) under the EEOICPA

Special Exposure Cohort(SEC) Classes:

Atomic Weapons Employer (AWE) employees who worked at the Combustion Engineering site in Windsor, Connecticut, from January 1, 1965, through December 31, 1972, for a number of work days aggregating at least 250 work days or in combination with work days within the parameters established for one or more other classes of employees in the SEC.

Compensation:

As of 01/08/2023, the total compensation paid under Part B of the EEOICPA, including medical compensation, for workers suffering from the effects of having worked at Combustion Engineering is $16,655,618. Click here for a current accounting of compensation paid to former Combustion Engineering Workers under the EEOICPA.

Combustion Engineering Workers:

If you or your parent worked at this or any other AWE facility and became ill, you may be entitled to compensation of up to $150K plus medical benefits from the US Department of Labor. Call EEOICPA Counsel Hugh Stephens at 1-855-EEOICPA (336-4272) or fill out the form to the right, whether or not you have filed a claim and even if your claim has already been accepted or denied.

We can help with all OWCP (Federal Workers Compensation) claims, impairments, wage loss and health care. 2495 Main Street, Suite 442 Buffalo, NY.

* OPERATIONAL HISTORY:

At least since the 195Os, CE has operated a facility on the site of approximately l,lOO acres near Windsor, Connecticut. During the late1940’s and early 1950’s, CE supplied certain non-nuclear component parts to AEC reactor projects (CE 1991). A 1955 agreement between CE and the AEC, accepted by parties on March 8 and March 3, respectively, appears to represent CE’s initial involvement in AEC’snaval reactor program. The agreement was followed some months later by AEC Contract No. AT(30-3)-198 that was to run until final settlement in July 1967. The initial scope of work of designing a submarine nuclear power plant facility ultimately led to the manufacture, assembly tests, and operation of the SlC Prototype Reactor facility on the CE site. The first amendment to the contractcalled for the development, design, and fabrication of fuel element subassemblies for the reactor — apparently CE’s entry into reactor core development and fuel fabrication work. The agreement and initial contract identified above cite special benefits to the Government in return for experience gained by CE to facilitate their entry into the fuel-fabrication market. Contracts with other AEC activities followed. According to CE, as many as 20 of some 100 contracts with the AEC during the decade beginning in 1955 involved the use of highly-enriched uranium (HEU) and other special nuclear material. The percentage of enrichment in the isotope U-235 in the HEU to which they refer was not provided. However, extracts from a June 1960 materials processing contract provided by CE indicates that Government furnished materials included 895 kilogramsof uranium enriched to approximately 93 percent U-235 in the form of uranium metal buttons for use in fabricating high-enriched uraniumassemblies. Contracts for similar non-naval reactor fabrication workusing uranium metal enriched in the range of 5 percent U-235followed. Therefore, it is apparent that the uranium furnished for use at the CE facility varied from approximately 5 percent to over90 percent enrichment of U-235.

In early 1959, 18 commercial firms were fabricating fuel elements at their own facilities. CE was one of two companies that were not required to license these activities because they were manufacturing exclusively for the Government (AEC 1960). CE presented descriptions of nine contracts for fabrication of core assemblies and fuel components, the last in 1962 (CE 1991). Additional contract information was provided later (Bickwit 1992) as reflected in References ii through qq.

By 1960, CE was designated as a source and special (SS) nuclear material accountability station subject to the policy and procedures of AEC Manual, Part 7400 – Materials Management, Chapter SCH-7401 Control of SS Material, Special Health and Safety Requirements. Enforcement was apparently accomplished by AEC audit and inspection of the CE facilities and operations. The results of an AEC nuclear safety inspection of the CE facility in 1962 included the statement that 8 kg of U-235 were not accounted for. It requested that CE inform the AEC of its conclusions regarding the location of the material and identify what assurances exist that the material did not exist in a form or location constituting a hazard to the plant or environment. It recommended corrective action “with regard to the storage of waste and scrap materials.” This is one of several admonishments for the loss of SS material contained in records reviewed.

In 1963 the AEC conducted health, safety, and fire protection surveys at CE (Glauberman and Weintraub 1964) — evidence of continued control and concern on the part of the AEC for worker protection and for proper operation of equipment and facilities. Available historical records indicate that AEC was concerned about releases to the environment. However, these records focus more on monetary penalties for material losses than on cleanup of any release to the environment resulting from what were then standard waste management practices on the part of CE.

In the early 1960’s, CE began commercial reactor fuel-fabrication. Although AEC contracts continued, some of the commercial work was performed in the same general areas used for AEC HEU work. However, CE has indicated that the commercial work did not involve the use of uranium enriched to the degree of that handled under the AEC contracts. The percentage or range of enrichment in the isotope U-235 was not provided. CE also indicated that some of the buildings used for commercial work were built after completion of the work for AEC. The nuclear fuel manufacturing facility was the example provided (CE 1991). According to CE, the first AEC license, obtained in 1961 for authority to possess source and special nuclear materials, did not include HEU (CE 1991).

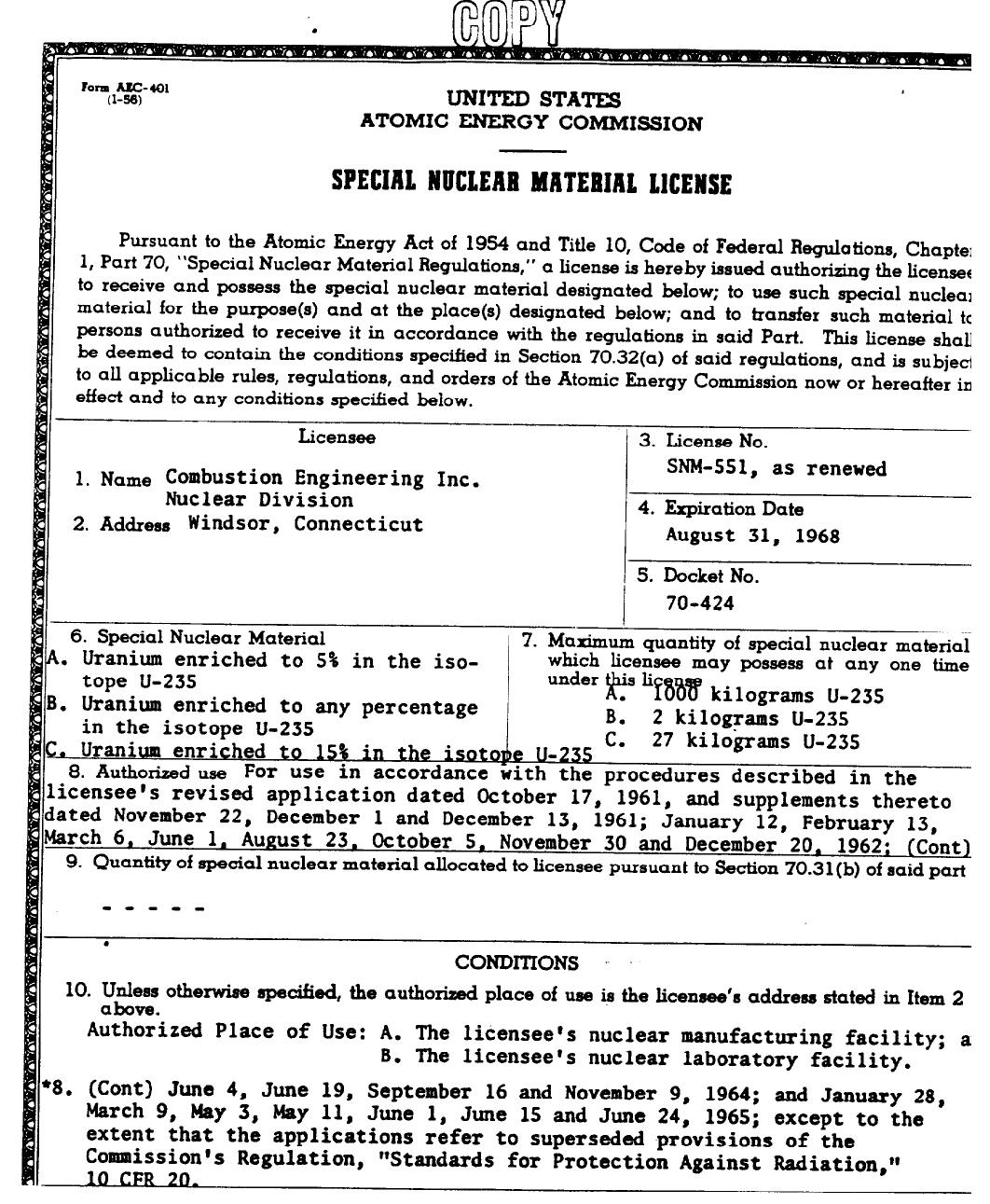

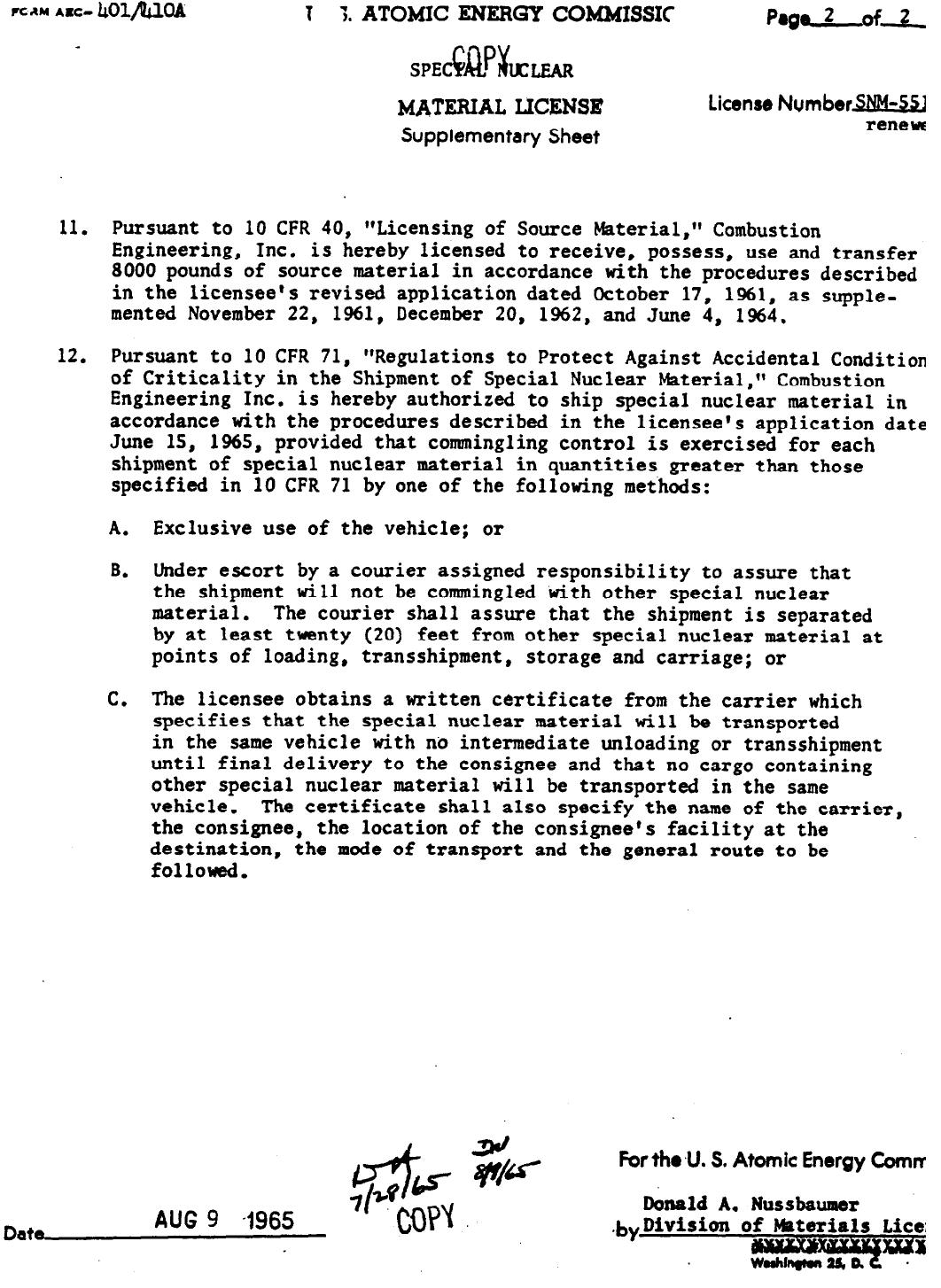

However, the license SNM-551, as renewed August 1965(Nussbaumer 1965), authorized possession of specific quantities of uranium enriched to 5%, 15% and a small quantity (2 kg) enriched to any percent. In October 1968, SNM-551 was terminated and the activities were reauthorized under license SNM-1067 (Nussbaumer1968); up to 5 kg were permitted to any enrichment. Today, amendment 21 to SNM-1067 (NRC 1991a) allows for possession of limited quantities of plutonium, encapsulated sources, and uranium in the following quantities and percentages of enrichment in the isotope U-235:

- -500,000 kg enriched to not more than 5 percent

- -4,800 g enriched to less than 20 percent

- -1000 g enriched to or more than 20 percent

For a period during the 1960s, CE was operating as an SS Accountability Station for source and special nuclear material provided for AEC work and subject to the policies and requirements of the AEC Manual chapter pertaining to control of SS material. And, at the same time, CE was doing work for commercial clients under authority granted by AEC license.

Information contained in several of the documents referenced in Section 7.0 indicate that licensed activities were, or could have been, conducted in or in closed proximity to some of the same facilities or areas used in support of AEC-sponsored activities. Examples are Buildings 1 through 6, buried waste lines between buildings, the creek bed, the sewage plant, and outside waste storage areas. Building 3 may be the only building used exclusively by CE for AEC contract work involving highly-enriched uranium (Young and Mitchell 1992).

At the start of the 1990s, approximately 10 percent of 2,500 employees at the site were involved with nuclear fuel fabrication and low-enriched uranium nuclear fuel research and development with uranium oxide powders.

*Source

**Source

DOCUMENTS:

NIOSH SEC Evaluation Report:

Petition 99 (Jan 1, 1965 to Dec 31, 1972)

SEC Petition Evaluation Report – Petition SEC-00099 – Report Rev #_0

Report Submittal Date: December 14, 2007