The EEOICPA was passed in 2000. It provides compensation to workers who became ill as a result of their employment manufacturing nuclear weapons in the USA, as well as their spouses, children, and grandchildren. Westinghouse Electric Corp. EEOICPA coverage is available for qualified former Workers and their families.

Are you eligible for compensation? If you or a family member worked at this or another AWE facility and became ill, you may be entitled to compensation of up to $150K plus medical benefits. Call EEOICPA Counsel Hugh Stephens at 1-855-548-4494 or fill out our free claim evaluation, We can help even if you’ve already filed, even if your claim was denied!

Here, we have compiled publicly available information and documentation about the facilities covered by the Act to clarify how their activities relate to the Energy Employees Occupational Illness Compensation Program Act.

Westinghouse Electric Corp.

Also Known As: North American Phillips Lighting,Westinghouse Electric Company Lamp Divisions, and North American Philips Lighting Corporation.

State: New Jersey

Location: Bloomfield

Time Period: AWE 1942 -1949; Residual Radiation 1950-March 1, 2011

Facility Type: Atomic Weapons Employer

Facility Description: Westinghouse Electric, located in Bloomfield, NJ, was one of the large commercial contributors to Manhattan Project research. Specific tasks related to uranium metal production and enrichment. Because developing the technology to produce pure uranium metal became a priority for the Manhattan Project, universities, and private companies with experience in related chemical processes participated in the task. From 1942- 1943, Westinghouse used a photochemical process for metallic uranium and supplied metallic uranium for the first self-sustaining chain reaction in Chicago. In addition to contributing to uranium metal production, Westinghouse Electric participated in activities related to uranium enrichment.

Westinghouse also worked with thorium under contract W-7409-ENG-31 for the Manhattan Project at this location.

During the period of residual contamination, as designated by the National Institute for Occupational Safety and Health and as noted in the dates above, employees of subsequent owners and operators of this facility are also covered under the Energy Employees Occupational Illness Compensation Program Act.

Listing:

Westinghouse Electric Corp. is listed as an Atomic Weapons Employer (AWE) under the EEOICPA.

Special Exposure Cohort (SEC) Classes:

All Atomic Weapons Employer employees who worked at Westinghouse Electric Corp., Bloomfield, New Jersey, from August 13, 1942 through December 31, 1949, for a number of work days aggregating at least 250 work days, occurring either solely under this employment, or in combination with work days within the parameters established for one or more other classes of employees included in the SEC.

Petitions Qualified for Evaluation

Location: Bloomfield, New Jersey

Job Titles and/or Job Duties: All Atomic Weapons Employer employees

Period of Employment: August 13, 1942 through December 31, 1949

Compensation:

As of 01/08/2023, the total compensation paid under Part B of the EEOICPA, including medical compensation, for workers suffering from the effects of having worked at the Westinghouse Electric Corp. (New Jersey) is $2,852,481. Click here for a current accounting of compensation paid to former Westinghouse Electric Corp. Workers under the EEOICPA.

Westinghouse Electric Corp. (New Jersey) Workers:

If you or your parent worked at this or any other AWE facility and became ill, you may be entitled to compensation of up to $150K plus medical benefits from the US Department of Labor. Call EEOICPA Counsel Hugh Stephens at 1-855-EEOICPA (336-4272) or fill out the form to the right, whether or not you have already filed a claim and even if your claim has been accepted or denied.

We can help with all OWCP (Federal Workers Compensation) claims, impairments, wage loss and health care. 2495 Main Street, Suite 442 Buffalo, NY 142414

*Site Function:

From 1941 to 1943 at its Bloomfield, New Jersey, facility,Westinghouse developed a photochemical technique to produce uranium metal using uranium oxide or nitrate and potassium fluoride. The

process was used to produce limited quantities of uranium. (Under the best weather conditions with good sunlight, the process could produce 1 ton/month.) The green salt produced by the reaction was electrolyzed to yield uranium metal that was subsequently cast into discs, tuballoy, pellets, and ingots. Five MED contracts have been identified: -W-7407-Eng-2 (LYTMET, August 1, 1942); W-7407-Eng-132 (equipment, December 18, 1943); W-7409-Eng-31 (thorium metal, August8, 1944); W-7405-Eng-312 (chemistry of uranium, date unknown); andW-7505-Eng-312(Z) (Micronex-development of high speed X-ray tubes and circuits, date unknown). LYTMET presumably refers to the photochemical uranium production. It is unknown whether the other contracts pertain to work performed at the Bloomfield facility.

Site Description:

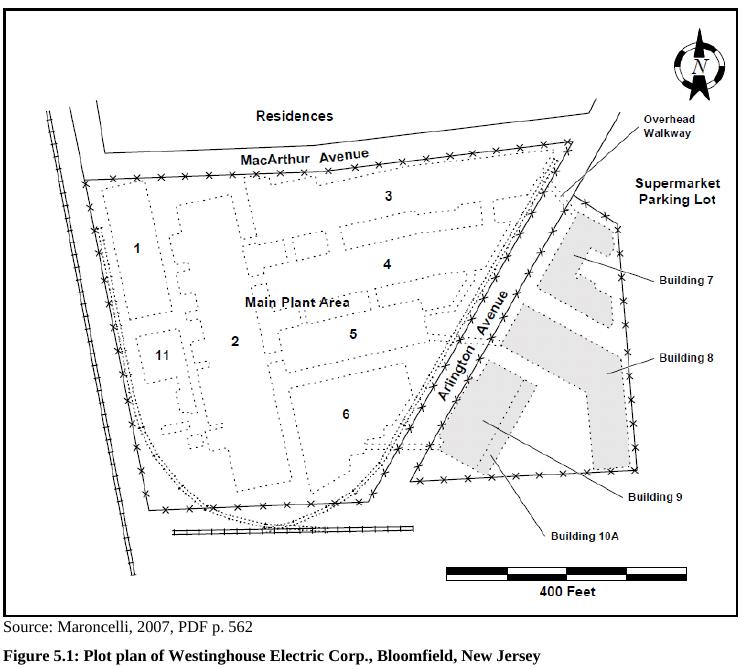

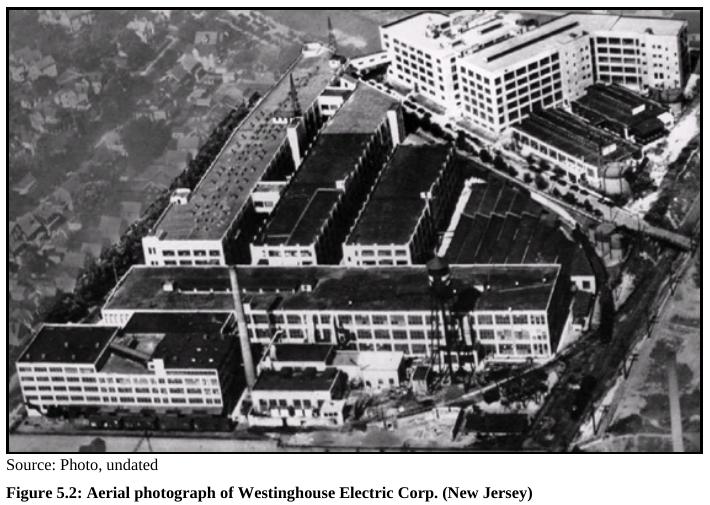

This facility is located in Bloomfield, New Jersey, and was owned and operated by the Westinghouse Electric Corporation until 1982 when it was acquired by North American Philips Lighting Corporation. Only Building 7 was used in the MED work. Uranium processed on the roofwas pipe-fed to the basement laboratory for purification. The pipe was stripped from the facility, along with other process equipment, atthe conclusion of the MED work. The disposition of this material has not been determined.

*Source

**Site Operations History

During World War II, WEC was contracted to produce uranium in support of the MED. Operations during this period, from August 1, 1942 through December 31, 1949, are also described in SEC Petition Evaluation Report for Petition SEC-00159 (NIOSH, 2010).

WEC developed a photochemical technique to produce uranium metal using uranium oxide or nitrate and potassium fluoride. The process was used to produce limited quantities of uranium. (Under the best weather conditions with good sunlight, the process could produce 1 ton/month.) The green salt produced by the reaction was electrolyzed to yield uranium metal that was subsequently cast into discs, pellets, and ingots (DOE, undated). The contract began on August 1, 1942 (DOE, undated) and was completed on October 15, 1943 (Unspecified, 1942-1943), and would have been capable of producing a total of 14.5 tons of uranium metal. At the end of this contract in 1945, the process equipment was removed (DOE, undated) and the uranium production facility was deactivated. After deactivation, the basement area was used primarily as a research testing laboratory (Westinghouse, 1980, PDF p. 30).

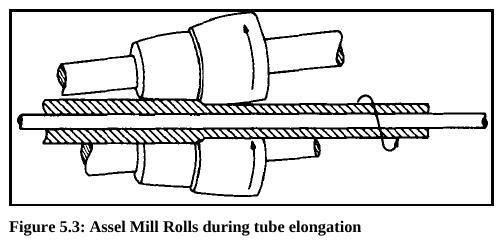

WEC also worked with thorium under contract W-7409-ENG-31 for the MED. They produced a total of 200 pounds of thorium metal in the form of bars, tubes, sheets, and wire in early 1945 (Uranium, undated, PDF p. 4). WEC also performed natural uranium machining operations for Fernald during short-term projects under contract from February 1958 through May 1958 and throughout June 1959. During these projects, WEC performed test rollings of uranium tubes on the Assel Mill to evaluate whether this process could be used to elongate hollow fuel rods for eventual use in a nuclear reactor as part of the nuclear weapons production complex (Simmons, 1959, PDF p. 74). The actual machining was scheduled to take one or two days (Kirkman, 1958, PDF p. 6), and the first test was attended by a Health and Safety Laboratory (HASL) representative, May 12 through May 16, 1958 (Ross, 1958). The work was performed on a No.1 Witter mill (also known as an Assel mill) (Simmons, 1958, PDF p. 100). The first test was unsuccessful because of excessive slippage between the work piece and the roll surfaces. A second rotary-elongation test was conducted on the same mill in June 1959. The actual machining during this second test occurred from June 25 through June 29, 1959, as indicated by the air monitoring dates (Monitoring, 1959). The mill-roll speed was reduced to 43 rpm (128 rpm was used in the previous test) (Steck, 1963).

NIOSH is not aware of any additional uranium machining operations at WEC after June 30, 1959 (Ansari, 1993, PDF p. 12).

Records indicate that on July 12, 1961, AEC issued a commercial license to WEC, License No. SMB- 353, to conduct R&D with thorium and uranium and to manufacture thorium-tungsten wire (for lighting applications) and thorium-containing welding rods. The license required WEC personnel to clean and maintain the work areas free of contamination, and to survey themselves upon exiting the work areas (SMB-353, 1961-1962, PDF p. 6). A second license, AEC License No. STB-467, was also issued to WEC for using thorium in the manufacture of mercury vapor lamps. The two licensed activities were consolidated under License No. SMB-353, and License No. STB-467 was subsequently terminated in November 1967 (Roberts, 1993, PDF p. 5).

In 1976 the Energy Research and Development Administration (ERDA) began a review of the radiological status of the facilities involved in supporting the MED under the Formerly Utilized Sites Remedial Action Program (FUSRAP) (Roberts, 1993, PDF p. 5). An October 1976 survey by ERDA staff identified contamination in the basement of Building 7 in floor drains, along the base of the walls and support columns where the walls joined the floor, and around support columns of a loading dock at the rear of the building. This survey was limited to Building 7 since it was the only portion of the WEC facility where MED work was performed (Roberts, 1993, PDF p. 6). After the ERDA survey results, WEC used the services of an outside contractor to clean contaminated areas at their own expense. Although some contamination remained above the then-current criteria for release for unrestricted use, ERDA did not recommend further remediation, but suggested that the residual contamination be licensed by the NRC as a means of further radiological control. In February 1978, WEC requested that the NRC amend their license to include this residual contamination (Roberts, 1993, PDF p. 6).

On September 29, 1977, Building 10 was released and approved for demolition by the NRC (SMB- 353, 1977-1980, PDF p. 6).

**Source

DOCUMENTS:

NIOSH SEC Petition Evaluation Reports

Petition 159 (Aug 13, 1942 to Dec 31, 1949)

SEC Petition Evaluation Report, Petition SEC-00159, Rev #: 0

Report Submittal Date: January 14, 2010

Petition 217 (Jan 1, 1950 to Mar 1, 2011)

SEC Petition Evaluation Report, Petition SEC-00217, Rev #:0

Report Submittal Date: April 14, 2015

SC&A

REVIEW OF SPECIAL EXPOSURE COHORT EVALUATION REPORT FOR SEC-00217