The EEOICPA was passed in 2000. It provides compensation to workers who became ill as a result of their employment manufacturing nuclear weapons in the USA, as well as their spouses, children, and grandchildren. Westinghouse Nuclear Fuels Division EEOICPA coverage is available for qualified former Workers and their families.

Are you eligible for compensation? If you or a family member worked at this or another AWE facility and became ill, you may be entitled to compensation of up to $150K plus medical benefits. Call EEOICPA Counsel Hugh Stephens at 1-855-548-4494 or fill out our free claim evaluation, We can help even if you’ve already filed, even if your claim was denied!

Here, we have compiled publicly available information and documentation about the facilities covered by the Act to clarify how their activities relate to the Energy Employees Occupational Illness Compensation Program Act.

Westinghouse Nuclear Fuels Division

Also Known As: Westinghouse Commercial Manufacturing

State: Pennsylvania

Location: Cheswick

Time Period: AWE 1971-1972; Residual Radiation 1973-1979

Facility Type: Atomic Weapons Employer

Facility Description: The Westinghouse Nuclear Fuels Division received shipments of nuclear materials from the AEC nuclear weapons complex in 1971 and 1972. The Cheswick site received a shipment of enriched uranium from the AEC’s Fernald plant in 1971. It also received a shipment of plutonium in 1972 from the West Valley facility. This plutonium originated out of Hanford. Because this material came from the nuclear weapons complex, the site qualifies as an Atomic Weapons Employer for these years.

Although the Westinghouse facility in Cheswick, PA, conducted substantial work with radioactive materials in other years, this work is not covered under EEOICPA because it was not related to nuclear weapons production. This includes the fabrication of nuclear fuels and reactor subsystems for naval, space, and civilian applications. Among the projects to which the Cheswick facility contributed were the Naval Nuclear Propulsion Program, the Nuclear Engine for Rocket Vehicle Application (NERVA) program, and the Liquid Metal Fast Breeder Reactor (LMFBR) program.

During the period of residual contamination, as designated by the National Institute for Occupational Safety and Health and as noted in the dates above, employees of subsequent owners and operators of this facility are also covered under the Energy Employees Occupational Illness Compensation Program Act.

Listing:

Westinghouse Nuclear Fuels Division is listed as an Atomic Weapons Employer (AWE) site under the EEOICPA.

Compensation:

As of 06/21/2015, the total compensation paid under Part B of the EEOICPA, including medical compensation, for workers suffering from the effects of having worked at Westinghouse Nuclear Fuels Division is $5,112,057.

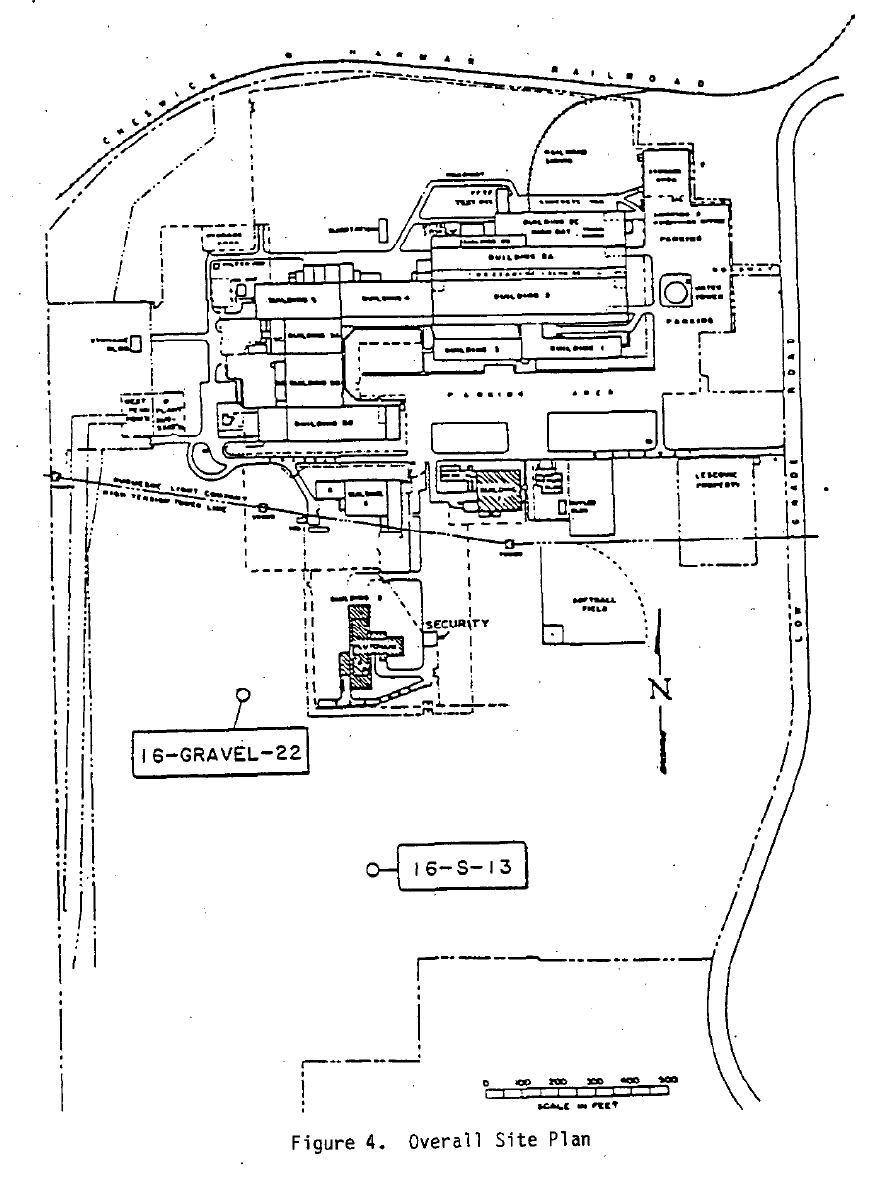

The Advanced Reactors Division was one of two divisions operating at the Westinghouse Electric Corporation’s Cheswick, Pennsylvania, site (Figure 4). This facility was constructed to fabricate demonstration uranium-plutonium fuel and develop equipment and techniques for fabrication of advanced plutonium-bearing fuels and rod assemblies. The W-ARD portion of the facility supported DOE predecessor research on and production of fast breeder reactors. It operated in parts of buildings 7 (‘the Plutonium Laboratory) and 8 (the Advanced Fuels Laboratory). The other (Nuclear Fuels) division primarily worked on commercial projects involving development and fabrication of recycled light water reactor fuel.

The Plutonium Laboratory in building 7 was established in 1966 for process and fabrication development and characterization of mixed uranium-plutonium carbide fuel materials and fuel elements. Sodium-bonded fuel pins were fabricated under contract to the Atomic Energy Commission (AEC) from 1967 to 1969 for irradiation testing inthe General Electric Test Reactor and in the Experimental Breeder Reactor-II (EBR-II).

In 1969, AEC began to phase out Government support of carbide fuelfor the Liquid Metal Fast Breeder Reactor (LMFBR) applications and instead emphasized oxide fuel for the Fast Flux Test Facility (FFTF) and the Clinch River Breeder Reactor Plant (CRBRP). To support FFTF and CRBRP, an Oxide Fabrication Line was established in building 8. Asignificant number of uranium, plutonium oxide fuel assemblies were fabricated in this facility under AEC contracts from 1969 to 1973 for irradiation testing in EBR-II.

W-ARD became a participant in the LMFBR Advanced Fuels Program in1974. Extensive facility modifications were made primarily in theBuilding 8 fabrication area to facilitate fabrication of the uranium, plutonium carbide material. Approximately 250 fuel pins containing uranium-plutonium carbide fuel were fabricated for testing in EBR-IIfrom 1974 through 1979. Fabrication of an initial complement of pins for testing in the Fast Test Reactor (FTR) was also completed toward the end of this time period.

In addition, a separate fuel fabrication facility also had been established for fabricating blanket fuel rods. During the last two years of operation, sufficient blanket rods for five assemblies had been fabricated–two assemblies for testing in EBR-II, and three for testing in FTR.

Toward the end of 1979 W-ARD operations began focusing on the decontamination effort. Work to package fuel for shipment off-site and cleaning of the glove boxes was initiated. Gross decontamination and removal of glove boxes was completed in 1980 and the final survey work and decontamination was accomplished in September 1981.