The EEOICPA was passed in 2000. It provides compensation to workers who became ill as a result of their employment manufacturing nuclear weapons in the USA, as well as their spouses, children, and grandchildren. Extrusion Plant (Reactive Metals Inc.) EEOICPA coverage is available for qualified former Workers and their families.

Are you eligible for compensation? If you or a family member worked at this or another DOE facility and became ill, you may be entitled to compensation of up to $400K plus medical benefits. Call EEOICPA Counsel Hugh Stephens at 1-855-548-4494 or fill out our free claim evaluation, We can help even if you’ve already filed, even if your claim was denied!

Here, we have compiled publicly available information and documentation about the facilities covered by the Act to clarify how their activities relate to the Energy Employees Occupational Illness Compensation Program Act.

Extrusion Plant (Reactive Metals Inc.)

Also Known As: Reactive Metals, Inc., RMI

State: Ohio

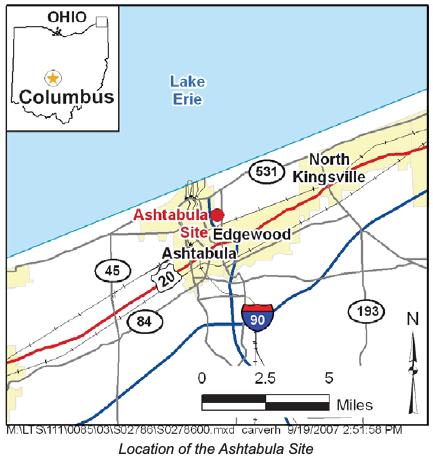

Location: Ashtabula

Time Period: 1962 — present

Facility Type: Department of Energy

Facility Description: From 1962 to 1988, Ashtabula (formerly known as Reactive Metals, Inc.) received uranium billets from Fernald’s Feed Materials Production Center and the Weldon Springs Plant and extruded them into feed stock for fabrication of fuel and target elements to be used in nuclear materials production reactors.

In 1988, the need for Cold War weapons production diminished and the DOE began closing the Extrusion Plant. By April of 1993 the DOE and RMI had formed a partnership to clean the site as part of decontamination and decommissioning. The DOE contracted with RMI Environmental Services (RMIES), a division of the RMI Titanium Company, to manage the cleanup project. RMIES has since changed its name to EARTHLINE Technologies. Reactive Metals Inc. of Ashtabula, Ohio was the corporate successor of the Bridgeport Brass Company of Adrian, Michigan, which performed similar extrusion work from 1954 to 1961. The semi-production extrusion press used at Adrian was transported and installed at Ashtabula.

In addition to its work for the Department of Energy (DOE) and its predecessor agencies, Ashtabula performed work for the Department of Defense and a number of commercial entities under a Nuclear Regulatory Commission (NRC) license.

*Site Description and History:

The Ashtabula, Ohio, Site comprises 42.5 acres of privately owned land adjacent to the city of Ashtabula, about 55 miles east of Cleveland. From 1962 to 1988 Reactive Metals Inc. (RMI) operated a facility on the property that manufactured metallic uranium tubes and rods and experimental quantities of thorium metal for use in the Hanford, Washington; and Savannah River, Georgia, weapons program reactors. The facility operated under contract to the U.S. Atomic Energy Commission and its successor agency the U.S. Department of Energy (DOE). RMI also extruded depleted uranium under a U.S. Nuclear Regulatory Commission (NRC) license and extruded nonradioactive materials, primarily copper-based, for the private sector.

RMI once operated a small wastewater evaporation pond near the northern boundary of the plant area for disposal of sodium nitrate solution, which also contained trace quantities of uranium and technetium-99 (Tc-99), a contaminant in recycled uranium. Trichloroethene (TCE) was used as a degreasing solvent at the plant from 1962 to 1966, and it is speculated that a single, unauthorized disposal of TCE occurred in the pond sometime before 1972. The pond overflowed periodically, and contaminated pond water flowed through a swale and over an embankment to low-lying areas north of the main plant area, contaminating soils in these areas as well. The pond was closed in 1984.

RMI began environmental remediation after the plant closed in 1988. In December 2003, DOE elected to terminate the contract with RMI and issue a competitive bid for the remaining cleanup at the site. In September 2005 the contract was awarded to LATA-Sharp Remediation Services to plan and complete the remediation.

Site remediation was grouped into two hazard areas, designated Hazard Area 1 and Hazard Area 2. Hazard Area 1 comprised approximately 12 acres, and remediation required removal of soils, soil piles, structures, asphalt, and concrete infrastructure contaminated with uranium and Tc-99. Thirty-five buildings were either demolished or decontaminated to free-release criteria.

Hazard Area 2 was designated a waste management unit and consisted of the 1-acre location of the former evaporation pond. This area was the only location where groundwater contamination was confirmed. Groundwater contaminants included TCE and degradation products, uranium, Tc-99, and nitrate. Cleanup in this area consisted of bioremediation and soil excavation to remove the source of groundwater contamination.

Remediation included excavation, transportation, and disposal of approximately 15,000 tons of low-level radioactive waste soil, more than 13,000 tons of low- level radioactive waste concrete debris, demolition and disposal of 12 contaminated structures, and excavation and disposal of about 4,500 tons of hazardous or mixed waste. All contaminated materials recovered during site remediation were shipped offsite to a licensed disposal facility.

Cleanup was completed in September 2006. The Oak Ridge Institute of Science and Education in Oak Ridge, Tennessee, performed an independent verification survey of the site and reviewed and concurred with the remediation contractor’s final radiological survey status reports. Regulatory closure of the site was achieved when the Ohio Department of Health terminated the site license in January 2007.

Listing:

Extrusion Plant (Reactive Metals Inc.) is listed as a Department of Energy (DOE) site under the EEOICPA.

Compensation:

As of 03/29/2015, the total compensation paid under Parts B and E of the EEOICPA, including medical compensation, for workers suffering from the effects of having worked at the Extrusion Plant (Reactive Metals Inc.) is $2,956,248.

Extrusion Plant (Reactive Metals Inc.) Workers:

If you or your parent worked at this or any other DOE or AWE facility and became ill, you may be entitled to compensation of up to $400K plus medical benefits from the US Department of Labor. Call EEOICPA Counsel Hugh Stephens at 1-855-EEOICPA (336-4272) or fill out the form to the right, whether or not you have already filed a claim and even if your claim has been accepted or denied.

We can help with all OWCP (Federal Workers Compensation) claims, impairments, wage loss and health care. 2495 Main Street, Suite 442 Buffalo, NY.

DOCUMENTS:

Technical Basis Documents

Summary of Extrusion Plant Site Information for Dose Reconstruction, Rev. 01

Effective Date: 03/07/2017

Summary of Extrusion Plant Site Information for Dose Reconstruction, Rev. 00

Effective Date: 04/26/2007