The EEOICPA was passed in 2000. It provides compensation to workers who became ill as a result of their employment manufacturing nuclear weapons in the USA, as well as their spouses, children, and grandchildren. Aliquippa Forge EEOICPA coverage is available for qualified former Workers and their families.

Are you eligible for compensation? If you or a family member worked at this or another AWE/DOE facility and became ill, you may be entitled to compensation of up to $400K plus medical benefits. Call EEOICPA Counsel Hugh Stephens at 1-855-548-4494 or fill out our free claim evaluation, We can help even if you’ve already filed, even if your claim was denied!

Here, we have compiled publicly available information and documentation about the facilities covered by the Act to clarify how their activities relate to the Energy Employees Occupational Illness Compensation Program Act.

Aliquippa Forge

Also Known As: Vulcan Crucible Steel Co., Universal Cyclops, Inc.

State: Pennsylvania

Location: Aliquippa

Time Period: AWE 1947-1950; Residual Radiation 1951-1987; 1989-1992; DOE 1988;

1993-1994 (remediation)

Facility Type: Atomic Weapons Employer (AWE), Department of Energy (DOE)

Facility Description: In the late 1940s, Aliquippa Forge (previously Vulcan Crucible) was a supplier of rolled uranium rods used in Hanford’s reactors. The AEC operated a rolling mill, two furnaces and cutting and extrusion equipment at Vulcan. Work at the site ended in 1950.

This site was designated as part of the Formerly Utilized Site Remediation Action Program (FUSRAP) in 1983 and remediation work took place was in 1988 and again in 1993-1994. This work was performed under the Bechtel National Inc. umbrella contract for DOE site environmental remediation.

During the period of residual contamination, as designated by the National Institute for Occupational Safety and Health and as noted in the dates above, employees of subsequent owners and operators of this facility are also covered under the Energy Employees Occupational Illness Compensation Program Act.

Listing:

Aliquippa Forge is listed as an Atomic Weapons Employer (AWE) and a Department of Energy (DOE) site under the EEOICPA.

Compensation:

As of 03/01/2015, the total compensation paid under Parts B and E of the EEOICPA, including medical compensation, for workers suffering from the effects of having worked at Aliquippa Forge is $450,000.

Aliquippa Forge Workers:

If you or your parent worked at this or any other DOE or AWE facility and became ill, you may be entitled to compensation of up to $400K plus medical benefits from the US Department of Labor. Call EEOICPA Counsel Hugh Stephens at 1-855-EEOICPA (336-4272) or fill out the form to the right, whether or not you have already filed a claim and even if your claim has been accepted or denied.

We can help with all OWCP (Federal Workers Compensation) claims, impairments, wage loss and health care. 2495 Main Street, Suite 442 Buffalo, NY.

*Site Description and History:

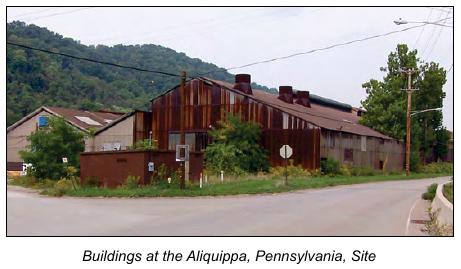

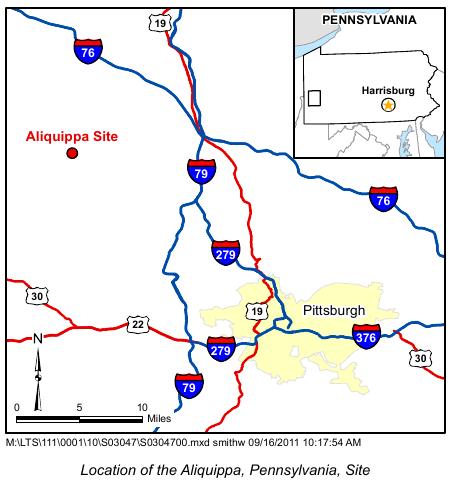

The Aliquippa, Pennsylvania, Site (formerly the Aliquippa Forge Site) is located at 100 First Street along the Ohio River in West Aliquippa, Pennsylvania, which is approximately 15.6 miles northwest of Pittsburgh. It is currently owned by Precision Kidd Steel Company. The site covers 8 acres in an industrial area.

From mid-1948 to late 1949, Vulcan Crucible Steel Company operated a uranium-rolling process for the U.S. Atomic Energy Commission (AEC) in Building 3. Uranium billets were sent to the 26,000-square-foot structure and formed into rods, which were then boxed and shipped to other facilities. Building 8, the other affected building on this site, extended north of Building 3 and housed two large air compressors; it had a total floor space of approximately 5,400 square feet. Building 8 has since been demolished. After completion of AEC operations, the Aliquippa site was decontaminated to then-applicable guidelines.

In 1978, Argonne National Laboratory conducted a radiological survey at the site and identified radioactive contamination exceeding U.S. Department of Energy (DOE) guidelines on floors, walls, and overhead beams. The site was designated for remediation under the Formerly Utilized Sites Remedial Action Program (FUSRAP) in August 1983. Fourteen areas of contamination in and around Building 3 were identified during a 1987 radiological characterization survey.

In 1992, the Oak Ridge Institute of Science and Education performed a radiological survey for remedial design of Building 3, the outdoor area along the western side of the building, and portions of Building 8.

Before remedial action began, the contaminated areas of both buildings were more accurately defined, revealing more residual uranium contamination than had been originally identified. In Building 3, contaminated areas included approximately 11,000 square feet of overhead area (11 trusses, roof panels, 2 exhaust turrets and associated ducts, light fixtures, wiring, and conduit); 990 cubic yards of soil and concrete from the west bay area; 1,000 square feet of contaminated walls; 19,000 square feet of contaminated floors; 5 cubic yards from a mica pit; 14 cubic yards from the west cutter pit; and 35 cubic yards of soil from along the western side of the building. The contamination for Building 8 consisted of 530 square feet of overhead area (three trusses and roof panels); 5,800 square feet of floor area; 1,140 square feet of wall area; and 13 cubic yards of brick and soil. These areas were decontaminated in 1993 and 1994 using HEPA-filtered vacuums for dust; wire brushes, scrapers, and sandpaper for rust; excavation for soil and concrete; and removal of equipment, exhaust turrets, ductwork, and ventilators. Approximately 100 cubic yards of building material waste was reduced in size and sent to a licensed low-level radioactive waste disposal facility in Clive, Utah.

DOE verified that no residual contamination above applicable guidelines was detected in any area of Building 3 or Building 8, except Building 3 roof panel joints on the western side, the area between the roof panels and purlins (dust and debris), and three concrete support pedestals. A risk assessment concluded that the material left in place would not pose an unacceptable present or future risk to workers or members of the public, and supplemental limits were approved for these areas. Supplemental limits may be applied in place of primary limits in situations in which the cost of remediation would be unreasonably high compared to the long-term benefits.

*Source

DOCUMENTS:

NIOSH:

Technical Basis Documents:

Basis for the Development of an Exposure Matrix for Aliquippa Forge, Pennsylvania,

Period of Operation: January 1, 1947, through February 28, 1950