The EEOICPA was passed in 2000. It provides compensation to workers who became ill as a result of their employment manufacturing nuclear weapons in the USA, as well as their spouses, children, and grandchildren. Herring-Hall Marvin Safe Co. EEOICPA coverage is available for qualified former Workers and their families.

Are you eligible for compensation? If you or a family member worked at this or another AWE/DOE facility and became ill, you may be entitled to compensation of up to $400K plus medical benefits. Call EEOICPA Counsel Hugh Stephens at 1-855-548-4494 or fill out our free claim evaluation, We can help even if you’ve already filed, even if your claim was denied!

Here, we have compiled publicly available information and documentation about the facilities covered by the Act to clarify how their activities relate to the Energy Employees Occupational Illness Compensation Program Act.

Herring-Hall Marvin Safe Co.

Also Known As: Herring Hall and Marvin Safe Co., Diebold Safe Co., HHM Safe

State: Ohio

Location: Hamilton

Time Period: AWE 1943-1951; Residual Radiation 1952-1993; DOE (remediation) 1994-1995

Facility Type: Atomic Weapons, Employer Department of Energy

Facility Description: Intermittently from the 1943 to 1951, the Herring- Hall-Marvin Safe Company machined natural uranium metal slugs from rolled stock under subcontract to DuPont and the University of Chicago.

During the period of residual contamination, as designated by the National Institute for Occupational Safety and Health and as noted in the dates above, employees of subsequent owners and operators of this facility are also covered under the Energy Employees Occupational Illness Compensation Program Act.

Listing:

Herring-Hall Marvin Safe Co. is listed as an Atomic Weapons Employer (AWE) site and as a Department of Energy (DOE) site under the EEOICPA.

Compensation:

As of 04/05/2015, the total compensation paid under Parts B and E of the EEOICPA, including medical compensation, for workers suffering from the effects of having worked at Herring-Hall Marvin Safe Co. is $2,084,558.

Herring-Hall Marvin Safe Co. Workers:

If you or your parent worked at this or any other AWE facility and became ill, you may be entitled to compensation of up to $150K plus medical benefits from the US Department of Labor. Call EEOICPA Counsel Hugh Stephens at 1-855-EEOICPA (336-4272) or fill out the form to the right, whether or not you have already filed a claim, and even if your claim has been accepted or denied.

We can help with all OWCP (Federal Workers Compensation) claims, impairments, wage loss and health care. 2495 Main Street, Suite 442 Buffalo, NY.

*Site Description and History:

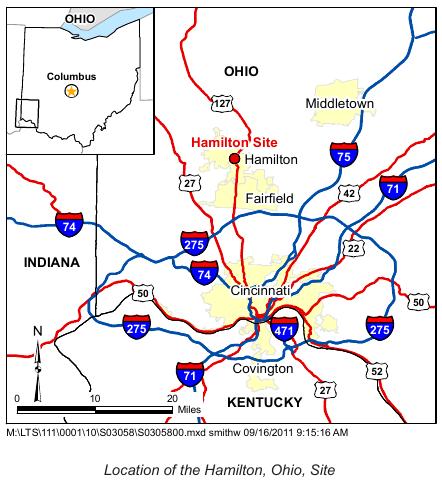

The Hamilton, Ohio, Site (formerly referred to as the Herring-Hall-Marvin Safe [HHMS] Company) is located at 1550 Grand Boulevard in Hamilton, Ohio. The three- story HHMS building was roughly rectangular and had an approximate area of 300,000 square feet. It was constructed mostly of concrete with a support structure of columns, beams, and cross braces.

From the 1940s to the early 1950s, the HHMS Company machined and shaped uranium metal under subcontract to Manhattan Engineer District (MED) contractors E.I. du Pont de Nemours and Company (Dupont) and the University of Chicago. Two work orders were performed, one in 1943 in support of MED activities and the other in 1951 in support of the U.S. Atomic Energy Commission (AEC). Uranium was machined on lathes in a large machine room on the first floor and also on the 9,000-square-foot third floor in the southeastern corner of the building. This MED/AEC work was discontinued in August 1951.

The U.S. Department of Energy (DOE) performed radiological surveys on August 29 and 30, 1988, and on April 24, 1989, on the first and second floors where the uranium work was reported to have taken place. Very little uranium was detected, and the surveys verified that all significant radioactive contamination had been removed from those areas during previous decontamination efforts. Consequently, the site was eliminated under the Formerly Utilized Sites Remedial Action Program (FUSRAP). However, in 1993, information obtained after the original survey indicated that uranium machining was also conducted on the building’s third floor. Oak Ridge National Laboratory performed a survey on the third floor, the stairwell, and the elevator. Radioactive contamination above DOE release criteria was detected on areas of the floor and walls, and the site was designated for remedial action under FUSRAP.

From December 1994 to March 1995, Bechtel National, Inc., as the project management contractor, defined the extent of contamination and performed remedial design engineering and remedial action at the Hamilton site. TMA Thermo Analytical (now Thermo NUtech) served as the radiological support subcontractor for sampling and analysis activities. Natural uranium isotopes were found to be the only significant source of contamination at the site.